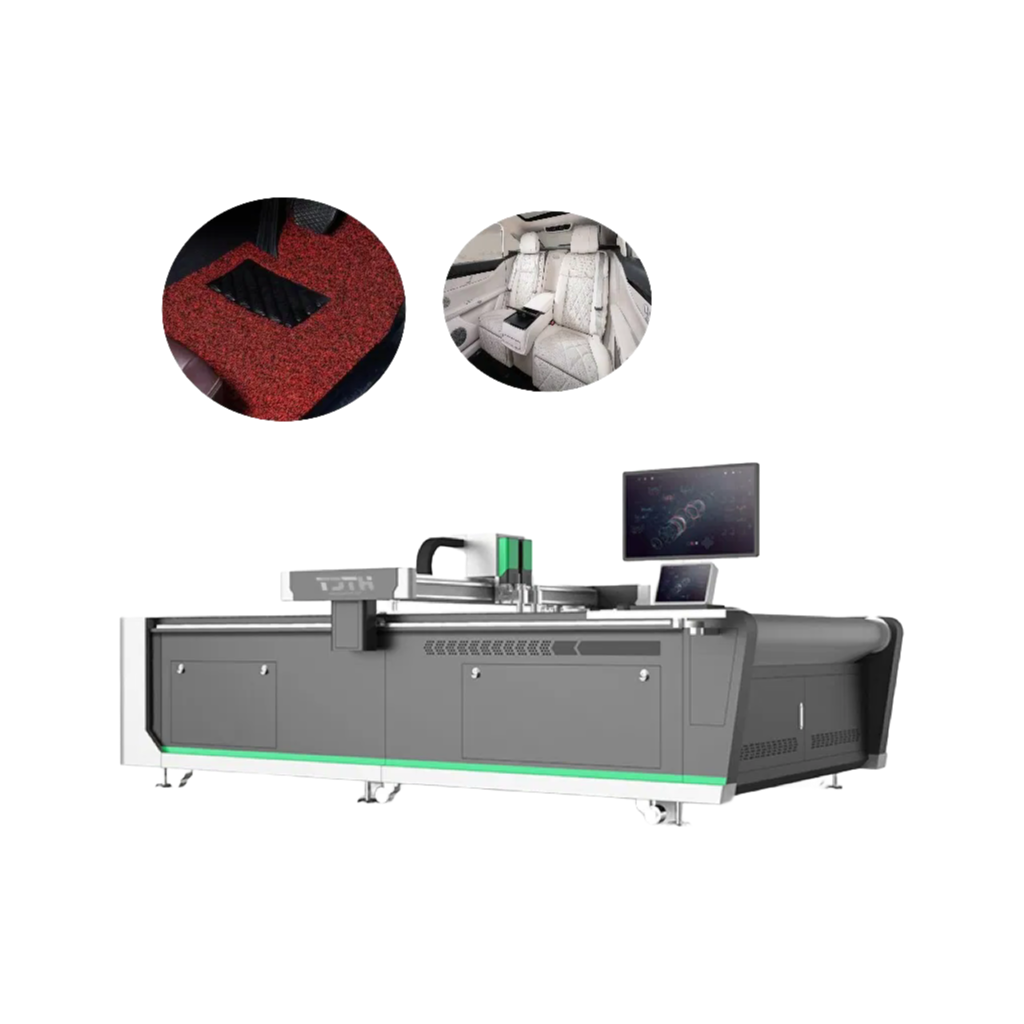

The automatic cutting machine is specifically designed for processing automotive interior materials such as car seat upholstery, floor mats, and other interior components. With advanced CNC technology, this equipment delivers exceptional precision and efficiency for industrial-scale production.

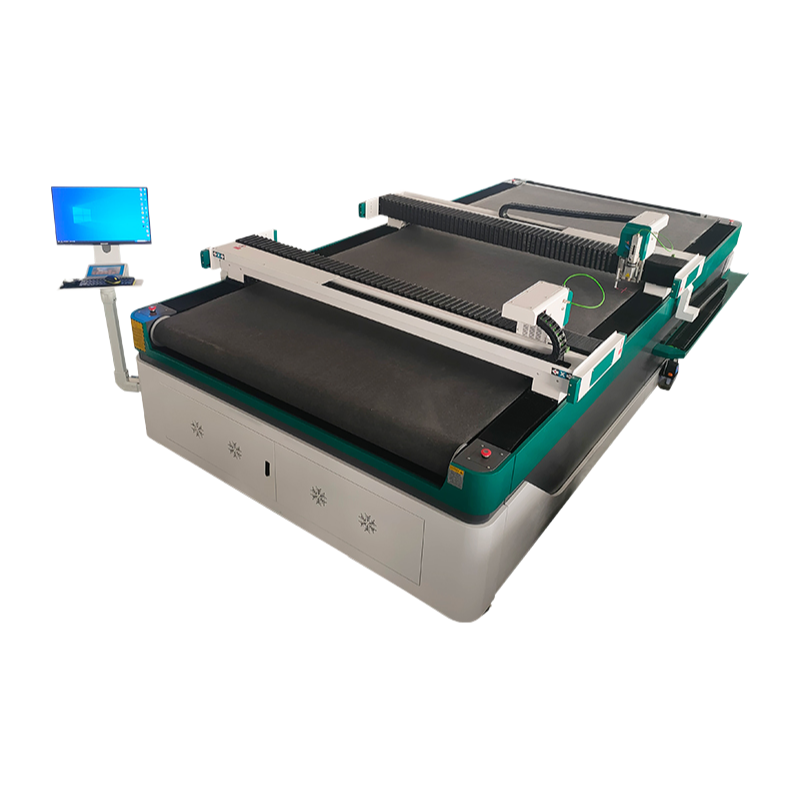

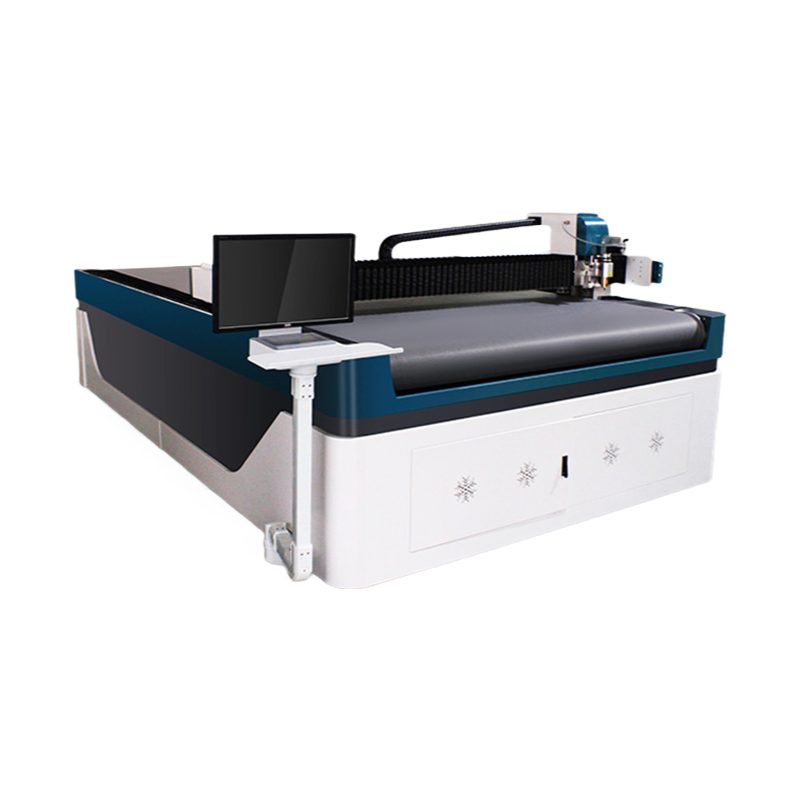

Featuring a high-performance vacuum adsorption system, the machine can handle materials ranging from 0.1mm to 110mm in thickness. The intelligent nesting software ensures optimal material utilization, achieving up to 95% efficiency while minimizing waste.

The cutting system operates at remarkable speeds up to 1.5 meters per second, with positioning accuracy of ±0.1mm. This makes it significantly more efficient than manual cutting methods while maintaining consistent quality across production runs.

Multiple model options are available to accommodate different production requirements, with customizable cutting areas to suit specific manufacturing needs. The standard models include VCM-1012 (1.0m×1.2m), VCM-1625 (1.6m×2.5m), VCM-1830 (1.8m×3.0m), VCM-2030 (2.0m×3.0m), and VCM-2230 (2.2m×3.0m).

Key features include automatic speed adjustment, secondary cutting vacuum compensation, inductive safety protection, and automatic feeding platform. The system supports various file formats including DXF, PLT, ISO, PDF, and HPGL for seamless integration with design software.

Constructed with premium components from international brands such as Panasonic servo motors, HIWIN guide rails, and Omron control systems, the machine delivers reliable performance with minimal maintenance requirements. The robust frame design supports heavy-duty operation while maintaining precision.

Ideal for automotive interior manufacturers, upholstery producers, and industrial fabricators requiring high-volume, precision cutting of flexible materials. The system significantly reduces labor costs while improving production efficiency and material utilization compared to traditional cutting methods.

Unbelievably fast shipping! The entire logistics process was handled with incredible efficiency. From the moment the order was confirmed to the delivery at my workshop, every step was transparent and timely. The packaging was absolutely top-notch; the machine was secured with professional-grade materials and arrived without a single scratch or dent, which is crucial for such precision equipment. Regarding quality, the build of the machine feels exceptionally robust and industrial. The materials used seem premium, and the initial setup and calibration were straightforward, indicating solid manufacturing standards. The service team was outstandingly responsive. They provided clear pre-sale information and were immediately available for post-delivery queries. Their professionalism and willingness to assist made the entire acquisition process smooth and worry-free. This level of attention to detail in logistics, the apparent initial quality of the product, and the supportive service have made a very strong first impression. I am thoroughly satisfied with this purchase experience so far and look forward to putting the machine to work.

Notably outstanding delivery speed—the package arrived two days earlier than estimated. No damages whatsoever, with secure industrial-grade packaging. The craftsmanship appears precise and durable upon unboxing, meeting professional expectations. Customer support was responsive and helpful during the ordering process. Nothing but smooth, efficient service from start to finish. Definitely a reliable supplier for industrial cutting needs.

WOW, the shipping was incredibly fast and well-handled! The machine arrived securely packaged with no damage, which was a huge relief. Quality-wise, everything feels solid and well-made, exceeding my expectations for durability. Customer service was outstanding too—they were responsive and helpful throughout the process. Overall, a fantastic experience from start to finish, and I'm very satisfied with how smoothly everything went.

Very satisfied with the overall experience! The shipping was incredibly fast, arriving much earlier than expected, which was a pleasant surprise. The packaging was secure and professional, ensuring the machine was well-protected during transit. In terms of quality, the construction feels robust and durable, with attention to detail that inspires confidence in its longevity. Customer service was exceptional; the team was responsive, polite, and provided clear updates throughout the process. They addressed my queries promptly and made the entire transaction smooth. Overall, a reliable purchase with no issues to report.