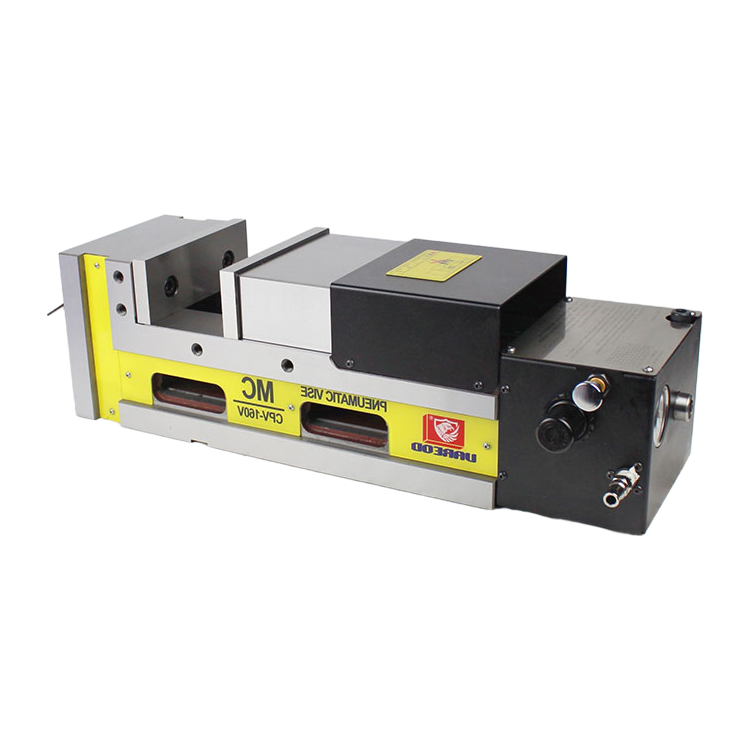

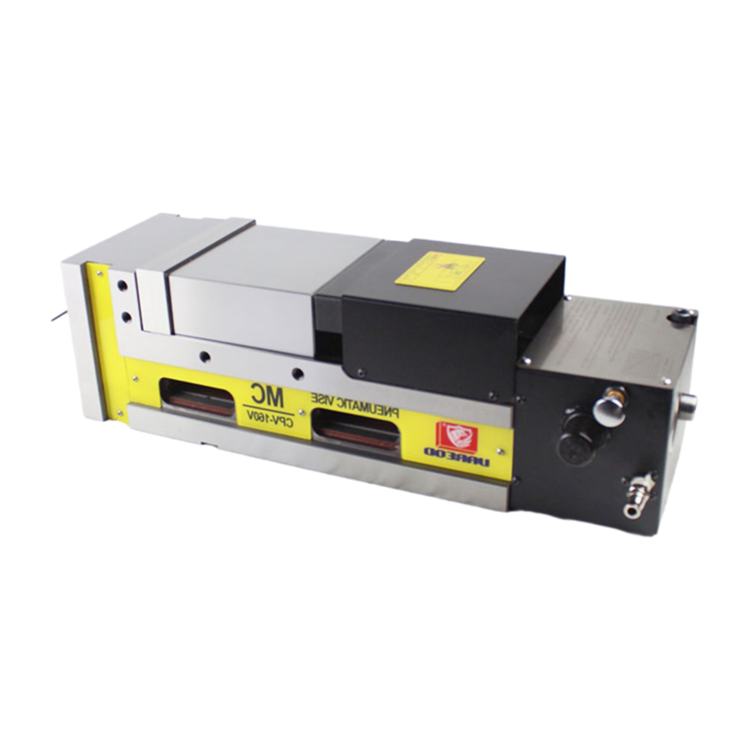

The CPV pneumatic vise series represents advanced clamping technology specifically engineered for modern CNC machining centers and industrial applications. These precision vises deliver exceptional performance through innovative design and robust construction.

Engineered for efficiency, the CPV pneumatic vise significantly reduces labor intensity while dramatically improving production efficiency. The system allows for custom clamp die installation tailored to specific product requirements, ensuring optimal workpiece holding for various machining operations.

The vise incorporates a sophisticated design comprising cylinder mechanisms, hydraulic components, clamp body, slider assembly, guide shafts, and adjustment nuts. This comprehensive system ensures reliable operation and long-term durability in demanding industrial environments.

Proper installation is crucial for optimal performance. The pneumatic vise must be securely fixed to the workbench with all compression screws tightened to specification. This prevents any loosening during processing, which could potentially damage the vise and compromise machining accuracy.

Key features include adjustable clamping force ranging from 0-6000KG, easily regulated through voltage control systems. The impressive 1.5-second switching speed enables rapid workpiece changes, while the 6MM clamping safety distance provides additional operational security.

The intelligent pressure regulation system automatically identifies the highest available air pressure source, maintaining consistent performance whether processing copper, aluminum, or conducting heavy cutting operations on cast iron materials. This automatic pressure regulation ensures reliable workpiece clamping under varying conditions.

Integration capabilities allow seamless docking with CNC system signals, enabling automated clamping and loosening sequences. This automation feature makes the CPV pneumatic vise ideal for high-volume production environments where consistency and speed are paramount.

Applications extend across multiple machining platforms including double-axis compound machines, CNC machining centers, milling machines, drilling equipment, and various other industrial machining systems. The versatility of these vises makes them suitable for diverse manufacturing requirements.

Constructed from high-grade cast iron with anvil design, these stationary-type vises provide the stability and rigidity necessary for precision machining operations. The robust material selection ensures longevity and consistent performance even under continuous heavy-duty use.

With CE certification and comprehensive quality control measures, the CPV pneumatic vise series meets international standards for industrial equipment. The combination of advanced features, reliable construction, and user-friendly operation makes these vises an excellent choice for modern manufacturing facilities seeking to optimize their machining processes.

Hats off to the entire process from start to finish. The shipping was remarkably fast and the package arrived in pristine condition, which was a huge relief. The courier service was efficient and provided timely updates, making the tracking process seamless. As for the product itself, the build quality is immediately apparent. It feels incredibly robust and well-manufactured, exactly as one would hope for a piece of industrial equipment. The finish is smooth and precise, with no visible defects or rough edges. It exudes a sense of durability that inspires confidence for heavy-duty use in a machining environment. Regarding the service aspect, the communication from the seller was prompt and professional. Any pre-shipment inquiries were answered clearly and without delay. The overall purchasing experience was straightforward and hassle-free. The product was securely packaged with appropriate materials to prevent any transit damage, which clearly showed attention to detail. While I have not yet integrated it into full operation, the initial inspection and handling suggest a very high standard of craftsmanship. The pneumatic connections appear solid and the mechanism operates smoothly. This level of care in logistics, apparent quality, and customer support makes for a highly satisfactory transaction. It’s refreshing to deal with a supplier that prioritizes these fundamental aspects so effectively.

Absolutely impressed with the delivery speed! The pneumatic vise arrived much earlier than expected, which was a pleasant surprise. The packaging was secure and professional, ensuring the product was well-protected during transit. As for quality, it feels robust and durable, with no visible defects or issues upon inspection. The service team was responsive and provided clear updates throughout the ordering process. Overall, a smooth and satisfying experience from start to finish.

Highly efficient delivery service ensured the pneumatic vise arrived promptly and securely packaged. The craftsmanship is exceptional, with robust construction that promises durability for industrial applications. Customer support was responsive and helpful throughout the ordering process, addressing inquiries swiftly. Overall, a reliable product backed by excellent logistics and attentive service, making it a valuable addition to any CNC machining setup.

Zippy delivery made this purchase a breeze; the item arrived ahead of schedule, which was a pleasant surprise. Zestfully, the build quality feels robust and durable, meeting my high expectations for industrial tools. Zealous customer support was evident throughout, with prompt responses to my inquiries. Zero complaints overall—this experience was smooth and satisfying from start to finish.