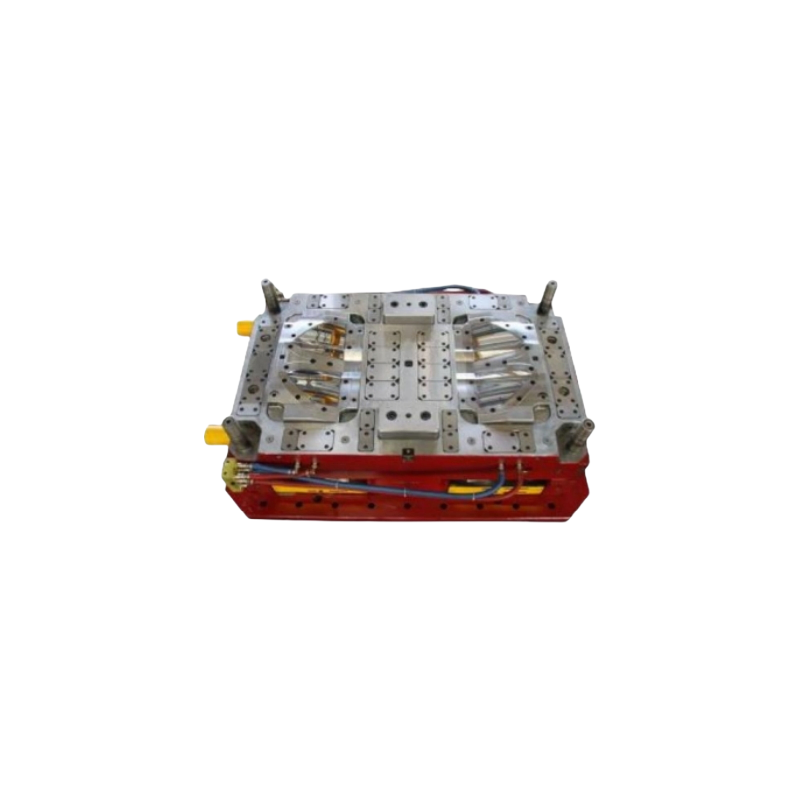

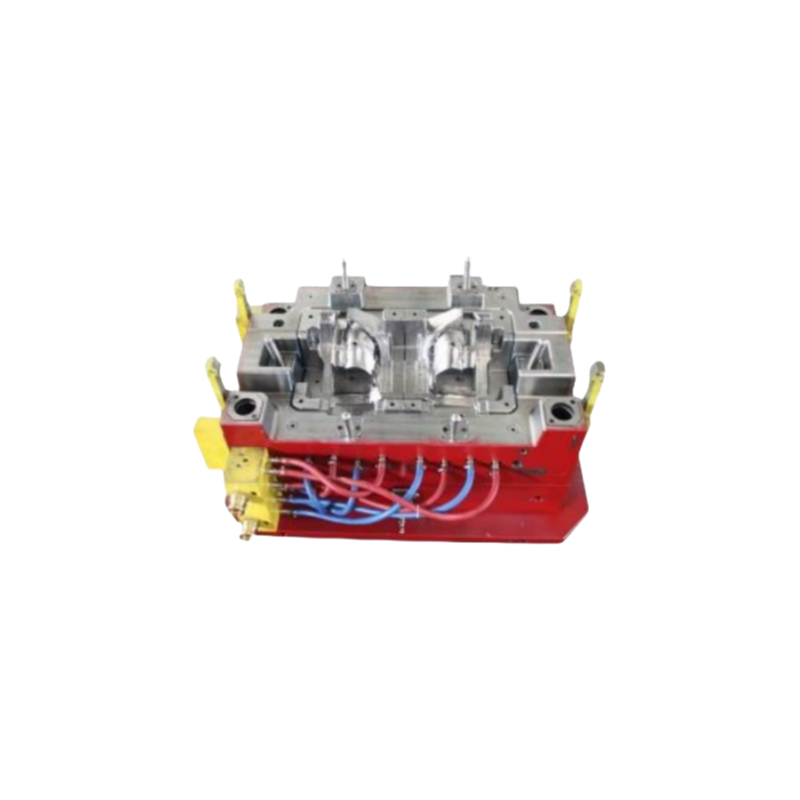

Our injection mould for swing car production is designed and manufactured to meet high standards of precision and durability. This mould is specifically tailored for creating swing car parts using PP plastic material, ensuring excellent performance and longevity in manufacturing processes. The single cavity design allows for efficient production cycles, with an average cycle time of 28 seconds, making it suitable for both small and medium-scale production runs.

The mould construction incorporates a big gate structure and cold runner system, which enhances the flow of plastic material and reduces waste. The surface finish is achieved through polishing, providing a smooth and high-quality appearance to the final products. The mould is built using premium materials such as P20 and 718 steel, known for their hardness and resistance to wear, ensuring a long service life even under continuous use.

We utilize advanced design software, including UG, for both 2D and 3D mould structure development. This allows for precise customization and optimization based on client requirements. The installation is semi-fixed, facilitating easy setup and maintenance. Each mould undergoes rigorous testing and inspection to ensure it meets the specified standards before shipment.

Our moulds are certified by SGS and BV, affirming their quality and compliance with international standards. They are packed in export wooden cases to ensure safe transportation and delivery. The mould is 100% new and comes with a 2-year warranty, covering accessories and excluding damages caused by human factors.

This product is ideal for manufacturers in the automotive and commodity sectors looking for reliable and efficient mould solutions. We offer customization options to fit specific production needs, ensuring that each mould delivers optimal performance and value.

Very satisfied with the entire process! The logistics were impressively fast and well-coordinated, with timely updates that made tracking effortless. Quality-wise, the mould appears robust and precisely crafted, reflecting high standards in manufacturing. Service was exceptional—the team was responsive, professional, and addressed all inquiries promptly. Overall, a smooth and reliable experience from start to finish.