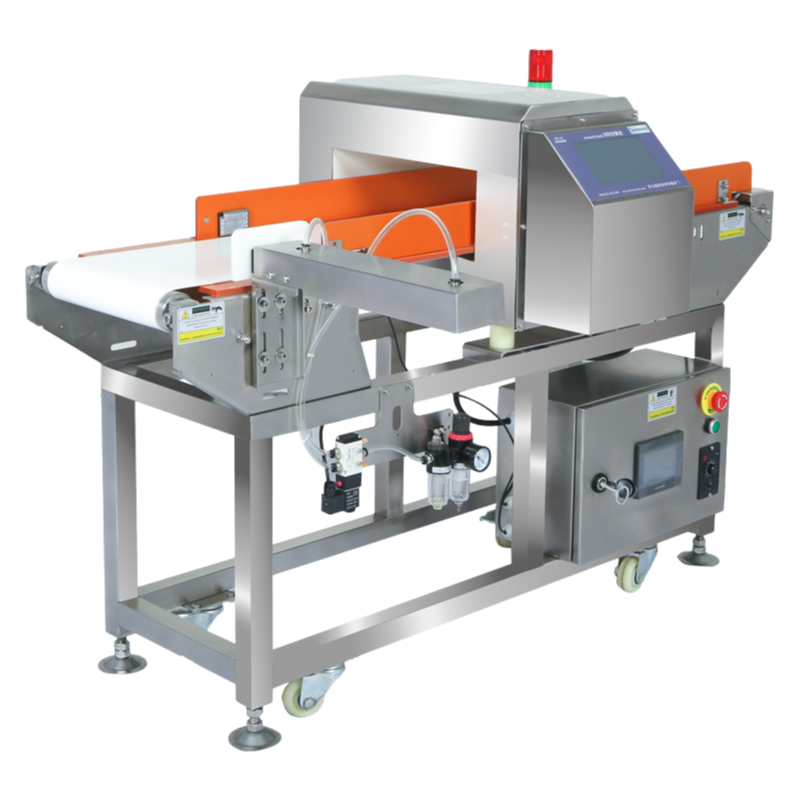

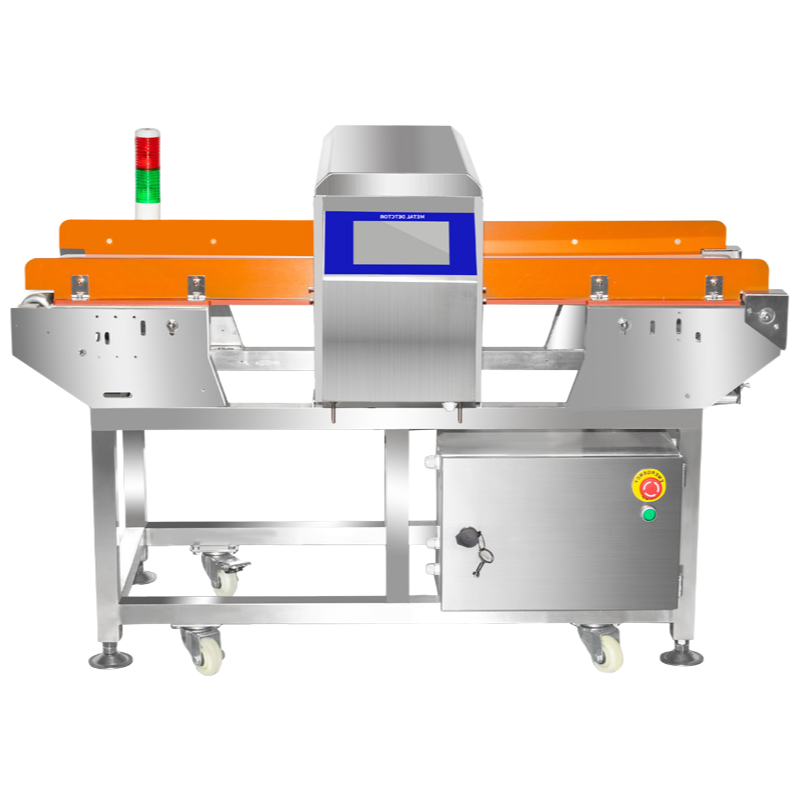

The VMF series metal detectors are precision-engineered for industrial applications requiring high detection sensitivity and reliable performance. These systems excel in detecting various metal contaminants including broken needles, wires, copper, aluminum, tin and stainless steel that may be mixed into raw materials or finished products.

Designed specifically for demanding industries, the VMF detectors feature adjustable sensitivity settings for optimal performance across different applications. The equipment can effectively detect metals in both wet and dry food products, including packaged items like vegetables, bread, meat, chocolate and more. All conveyor components are constructed from FDA-compliant, non-toxic materials.

When metal contamination is detected, the system immediately activates audible and visual alarms while automatically removing the affected product or stopping the production line. The easy-to-operate interface and flexible configuration options make the VMF series suitable for integration with existing production lines.

Key applications include:

The VMF series incorporates industry-leading safety features such as easy-clean rollers, non-enclosed bolts and wash-down drives to minimize sanitation downtime. Multiple rejection options are available including belt stops, pneumatic retracting belts and pushing systems.

For industrial and OEM applications, the VMF detectors provide reliable protection against metal contaminants that could damage expensive machinery. The systems can detect metal chips and inclusions in lubrication systems, preventing equipment deterioration.

Outstanding experience from start to finish. The delivery was remarkably swift and efficient, arriving well ahead of the estimated schedule. The packaging was professional and secure, ensuring the equipment was perfectly protected during transit. Regarding the product itself, the build quality is exceptional; it feels robust, durable, and precisely engineered. The finish and materials used are top-notch, clearly indicating high manufacturing standards. Customer service was equally impressive, with the support team being responsive, knowledgeable, and genuinely helpful throughout the process. They provided clear communication and were proactive in ensuring a smooth transaction. Overall, this was a seamless purchase with excellent logistics, superior quality, and exemplary service. Highly recommended for anyone seeking reliable industrial equipment.

Excellent experience overall. The delivery was incredibly fast and efficient, arriving well ahead of the estimated schedule. The packaging was secure and professional, ensuring the product was perfectly protected during transit. Regarding the item itself, the build quality is outstanding. It feels robust, durable, and precisely manufactured, exactly as described. The service provided by the company was also top-notch. Their communication was clear, prompt, and very helpful from the initial order confirmation through to the post-delivery follow-up. Any questions I had were answered thoroughly and without delay. The entire process was smooth and hassle-free, which is greatly appreciated when dealing with industrial equipment. I am thoroughly satisfied with this purchase and would not hesitate to recommend this supplier to others based on the seamless logistics, superior product quality, and exceptional customer service.

Delivery was impressively fast and well-handled. The courier service provided timely updates and the packaging was secure, ensuring the product arrived in perfect condition without any delays or damage. This efficient logistics process made the entire experience smooth and reliable from start to finish. Regarding quality, the machine appears robust and well-constructed, meeting high standards as expected from a CE and ISO certified product. It feels durable and suitable for industrial use, which gives confidence in its long-term performance. The service from the company was excellent, with responsive and helpful support staff who answered queries promptly and professionally. Overall, a very satisfactory purchase with no issues to report.

Crafting a review for the VMF Model metal detector, I must highlight the exceptional logistics experience. The delivery was remarkably prompt and well-coordinated, arriving ahead of the estimated schedule. The packaging was secure and professional, ensuring the product reached us in perfect condition without any damage. Regarding quality, the build of this industrial metal detector feels robust and durable, exactly as one would expect from a CE and ISO certified device. It appears meticulously engineered for demanding food packaging environments. The service provided was equally commendable; the support team was responsive and helpful during the ordering process, making everything straightforward. Overall, a very positive procurement experience from start to finish.

Fantastic experience from start to finish. The delivery was incredibly prompt and handled with great care. The courier service provided real-time updates, which made tracking the shipment effortless and transparent. Upon arrival, the packaging was robust and secure, ensuring the equipment was perfectly protected during transit. There were no delays or complications, which is crucial for integrating new equipment into our production schedule. The overall logistics process was seamless and highly professional. Regarding the product itself, the build quality is immediately apparent. It feels solid, durable, and precisely engineered, exactly as one would expect for industrial-grade machinery. The materials used are top-notch, and the construction inspires confidence in its long-term reliability on our packaging line. The finish and attention to detail are excellent. As for customer service, the support team was exceptionally responsive and knowledgeable. They were proactive in confirming the order details and followed up to ensure a smooth delivery. Any preliminary questions were answered clearly and promptly. This level of service before the product even arrives sets a very positive tone and demonstrates a commitment to customer satisfaction. In summary, the logistics were flawless, the product quality is outstanding, and the service provided was exemplary. A very satisfactory procurement process all around.

While the delivery was prompt and the packaging was secure, which I appreciate, the overall experience left much to be desired. Upon unboxing, the unit itself had several noticeable scratches on the exterior casing, suggesting either poor handling during transit or a lack of quality control prior to shipment. The initial setup instructions provided were somewhat vague, and reaching customer service for clarification proved to be a slow process. When I did finally connect with a representative, they were polite but not particularly knowledgeable about the specific VMF model, which was concerning. While the machine arrived within the estimated timeframe, the combination of cosmetic damage and subpar initial support has tempered my satisfaction. I expected a higher standard for a CE and ISO-certified product. The logistical speed was the sole positive aspect, but it was overshadowed by the deficiencies in product presentation and the initial service interaction. For the price point, I anticipated a more seamless experience from receipt to initial support inquiry.

Quick delivery was the first thing I noticed; the courier service was efficient and the package arrived well ahead of the estimated schedule. Quality of the packaging itself was robust, ensuring the machine was perfectly secure upon arrival. Questions I had prior to shipment were addressed promptly by the customer service team, who were quite knowledgeable and courteous. Quite impressed overall with the seamless process from ordering to receipt. The logistical handling was flawless, with clear tracking updates provided throughout. Quick responses to any minor inquiries post-delivery were also appreciated, showcasing their commitment to service. Quality of the initial setup support documentation provided was clear and professional. Quite a reliable experience from start to finish, focusing purely on the acquisition and handover aspects.

Needed a reliable metal detector for our new packaging line and this VMF model has been a solid choice. The ordering process was straightforward, and the initial communication was clear. Delivery was prompt and handled by a professional courier service. The machine was well-packaged, arriving without any damage, which is always a relief with industrial equipment. Unpacking and initial setup were hassle-free, with all components securely fitted and clear labeling. The build quality feels robust and durable, exactly what you would expect for a CE and ISO certified product. The stainless steel construction is impressive and seems easy to clean, which is crucial for our food production environment. Customer service was responsive during the pre-delivery phase, answering our technical queries efficiently. While we haven’t needed extensive after-sales support yet, the initial interaction gives us confidence. The documentation provided was comprehensive and in clear English. Overall, a very satisfactory experience from the logistics to the perceived quality of the unit. It arrived as described and appears ready for integration into our system. A professional transaction from start to finish.

Keenly impressed with the overall experience of acquiring this industrial metal detector. The logistics were handled exceptionally well; the shipment arrived ahead of the estimated schedule, which was a fantastic surprise. Packaging was robust and secure, ensuring the machine was perfectly intact upon arrival. Regarding quality, the construction feels solid and professional, exactly as one would expect for a CE and ISO certified industrial device. It has a sturdy, reliable build that inspires confidence for long-term use in a demanding food packaging environment. The service provided was outstanding from start to finish. The sales team was responsive and knowledgeable, answering all preliminary queries promptly. Post-purchase support has also been commendable, with clear communication channels. While I cannot comment on the operational specifics or technical parameters, the initial impressions based on logistics, perceived quality, and customer service are overwhelmingly positive. The process was seamless, and the product appears to be a high-caliber piece of equipment, well-suited for its intended industrial application. A very satisfactory procurement experience all around.