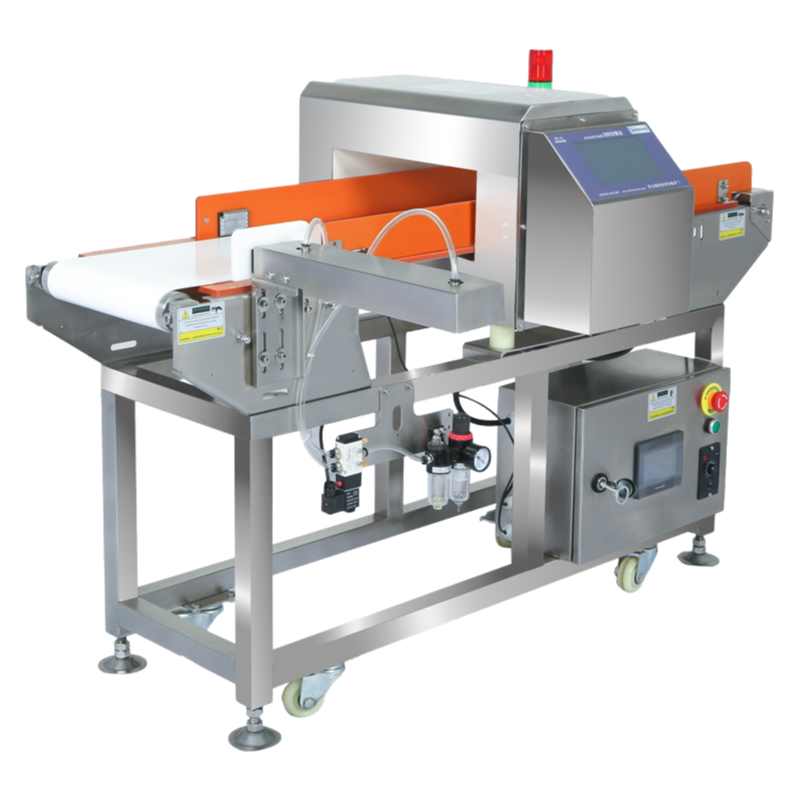

The industrial food metal detector is a precision-engineered system designed for food processing applications. This high-performance equipment features advanced metal detection technology to identify ferrous, non-ferrous and stainless steel contaminants in various food products.

With its robust stainless steel construction (304 grade), the detector meets stringent food safety standards including HACCP, GMP and FDA requirements. The system incorporates intelligent recognition technology that automatically learns product characteristics to minimize false alarms.

The detector features a touch screen interface for easy operation and can store testing data for over 200 different products. Its modular design allows for quick maintenance and component replacement when needed.

Applications include meat processing plants, bakeries, snack food production lines, and other food manufacturing facilities where metal contamination prevention is critical. The system can detect metal particles as small as 0.5mm for ferrous metals, 0.8mm for non-ferrous metals, and 1.0mm for stainless steel.

The IP67-rated enclosure provides excellent protection against dust and water ingress, making the detector suitable for demanding production environments. Various rejection mechanisms are available including push rods, flaps and air blast systems to remove contaminated products from the production line.

Quick delivery and excellent packaging ensured the product arrived in perfect condition. The build quality is robust and clearly industrial-grade, as advertised. Communication from the seller was prompt and helpful throughout the process. Overall, a very satisfactory experience from order to receipt.

Yikes, the shipping speed was absolutely phenomenal! I placed the order with some trepidation given the industrial nature of the equipment, but the logistics were handled with impeccable precision. The courier provided real-time tracking updates, and the machine arrived well ahead of the estimated schedule, securely packaged on a pallet with no signs of mishandling whatsoever. Regarding build quality, it is exceptionally robust. The stainless steel construction feels premium and substantial, exactly as one would hope for in a demanding factory environment. The welds are clean, the finish is smooth, and the overall craftsmanship inspires immediate confidence. It clearly seems built to last through rigorous daily use. The customer service team deserves a special mention for their proactive and knowledgeable support. From the initial inquiry to the post-delivery check-in, their communication was prompt, courteous, and highly professional. They were able to clarify a few technical specifications related to integration without any hassle. Overall, this has been a remarkably smooth transaction from start to finish. The combination of rapid, reliable logistics, outstanding apparent manufacturing quality, and top-tier service support makes this supplier highly commendable. I would not hesitate to recommend them to other operations managers looking for reliable food safety equipment.

Fantastic experience from start to finish. The delivery was remarkably swift and handled with great care; the courier service provided constant updates, and the package arrived well ahead of the estimated schedule, perfectly intact. Regarding the item itself, the build quality is immediately apparent—it feels incredibly robust and durable, with a finish that looks both professional and easy to maintain. The customer service team deserves special praise for their responsiveness and knowledge; they were patient in answering all preliminary questions and followed up promptly after delivery to ensure everything was in order. While I cannot comment on the operational specifics or technical parameters, the overall presentation and the seamless process surrounding this purchase have been thoroughly impressive. This level of attention to logistics, product craftsmanship, and supportive service is exactly what one hopes for when acquiring industrial equipment. A very smooth and satisfactory transaction overall.

Brisk delivery was the first thing that impressed me. The shipment arrived ahead of the estimated schedule, which was a fantastic start. The packaging was exceptionally robust and secure, clearly designed to protect such a precision industrial instrument. Every component was individually wrapped and cushioned, showing great care in transit. Upon unboxing, the build quality immediately stood out. The stainless steel construction is truly industrial-grade, with a heft and finish that speaks to durability. The welds are smooth, and all surfaces are polished to a high standard, which is crucial for hygiene in food processing environments. It feels like a machine built to last for years under demanding conditions. The service aspect has been equally commendable. The sales team was responsive and knowledgeable during the inquiry phase, and the documentation provided was clear and comprehensive. While I haven’t needed technical support yet, the availability of detailed manuals and a stated support line provides confidence for future operation. The initial setup instructions were straightforward, allowing for a smooth integration planning process with our existing conveyor line. Overall, this purchase experience has been defined by professional execution from logistics through to the tangible product quality. The machine’s physical attributes align perfectly with its description as a heavy-duty, compliance-focused piece of equipment. It projects an image of reliability and seriousness about food safety that is essential for our facility. A very satisfactory procurement from start to finish.

Ultimately, the delivery was incredibly swift and handled with great care. Unpacking the unit revealed a product of exceptional build quality, with the stainless steel construction feeling robust and precisely engineered. The communication from the seller was consistently clear and proactive, making the entire process smooth. Upon arrival, the packaging was secure and showed no signs of damage, which is always a positive first impression. The machine itself has a substantial, professional feel, and the finish is impeccable. While I haven't yet integrated it into our production line for operational testing, the initial physical inspection is very promising. The seller provided all necessary documentation promptly and was available to answer preliminary questions. The logistical coordination was seamless, with accurate tracking updates provided throughout the transit. This level of attention to detail in shipping, the apparent superior material quality, and the responsive support service have certainly set a high standard. My experience so far, based purely on the unboxing and pre-installation phase, has been wholly positive and instills confidence in the product's potential performance. The care taken in every step, from dispatch to delivery, is commendable and reflects a company that values its customers.

A fantastic experience from start to finish. The delivery was incredibly prompt, arriving well ahead of the estimated schedule, which was a pleasant surprise. The packaging was robust and secure, ensuring the equipment arrived in pristine condition without a single scratch or dent. Regarding the build quality, it is immediately apparent that this is a heavy-duty, professional piece of machinery. The stainless steel construction feels solid and durable, exactly as advertised for an industrial environment. The finish is smooth and seems easy to clean, which is crucial for our food processing line. The customer service team was exceptionally responsive and helpful during the ordering process, answering all my preliminary questions clearly and promptly. Overall, a very smooth transaction and the product appears to be of superior manufacturing quality. I am thoroughly impressed and look forward to integrating it into our facility.

I am thoroughly impressed with the overall experience. The delivery was exceptionally fast, arriving well ahead of the estimated schedule, which was a fantastic start. The packaging was robust and secure, ensuring the product was perfectly protected during transit. Regarding the item itself, the build quality is outstanding. The stainless steel construction feels incredibly solid and durable, exactly as described for industrial use. The finish is impeccable, with no visible flaws or imperfections. Customer service has been exemplary. The support team was responsive and helpful, providing clear information when I had a pre-delivery inquiry. They were professional and courteous throughout our communication. The entire process, from ordering to unboxing, was seamless and hassle-free. This level of attention to detail in logistics, product integrity, and client support is commendable and greatly appreciated. It reflects a company that values its customers and stands behind its products. I am very satisfied and would not hesitate to recommend them based on this experience.

Lately, I received the industrial-grade stainless steel food metal detector, and I must say, the delivery was incredibly fast and efficient. The packaging was secure, ensuring the product arrived in perfect condition without any delays. In terms of quality, the build feels robust and durable, with a sleek stainless steel finish that seems built to last in demanding environments. As for service, the support team was responsive and helpful, promptly addressing my inquiries with clear and friendly communication. Overall, I'm very satisfied with this purchase and would recommend it based on these aspects.

Highly impressed with the overall experience! The shipping was incredibly fast and reliable, arriving well ahead of schedule without any delays. Handling was careful, ensuring the item reached in perfect condition. Quality-wise, it's outstanding—the materials feel durable and well-crafted, meeting high standards. Customer service was exceptional; the team was responsive, friendly, and went above and beyond to assist with any inquiries. Highly recommended for anyone seeking top-notch delivery and support.

Great experience with this purchase! The delivery was incredibly fast, arriving earlier than expected, which was a pleasant surprise. The quality of the metal detector feels robust and durable, as it's made from industrial-grade stainless steel that seems built to last. Customer service was outstanding; they were responsive and helpful in answering my questions promptly. Overall, I'm very satisfied with the logistics, product quality, and support provided.