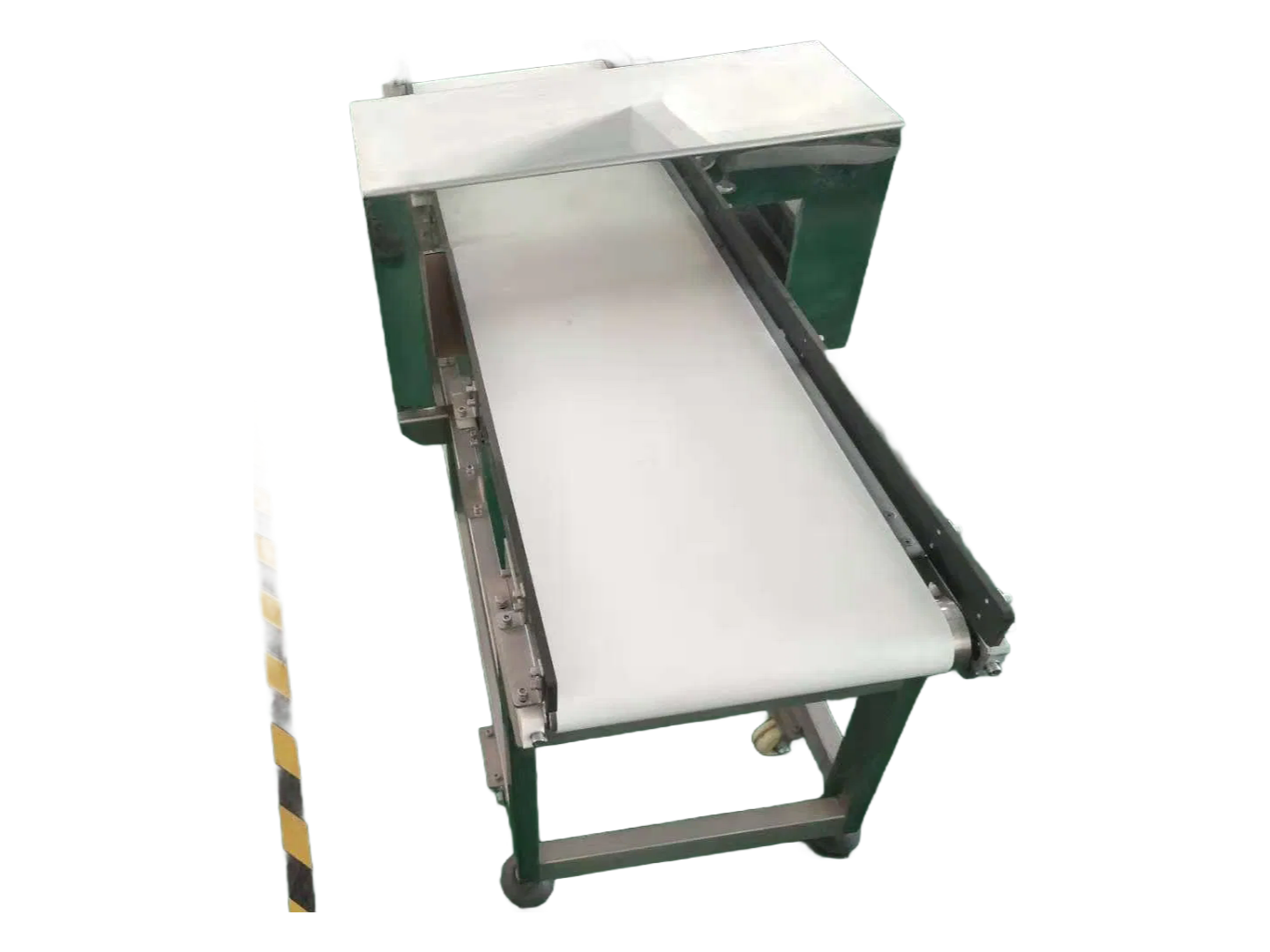

The AMC500 series metal detector is designed for precise detection of metal contaminants in various industries including food processing, pharmaceutical manufacturing, textile production and more. This advanced equipment complies with HACCP and GMP standards, ensuring reliable performance in quality control processes.

This detector utilizes balanced coil technology combined with phase-adapted DSP processing to effectively eliminate product effect while maintaining high sensitivity. The system can detect ferrous metals as small as 0.6mm in optimal conditions, with detection capability varying by model size.

Key features include:

- Large LCD display with multilingual interface

- Self-learning function for automatic product feature storage

- Capacity to store over 100 product testing profiles

- Automatic flap rejection system to improve production efficiency

- Modular design for easy maintenance and operation

The equipment is particularly effective for detecting metal contaminants in:

- Packaged food products (cookies, sauces, dumplings)

- Processed meats and frozen foods

- Bakery items and confectionery

- Pharmaceutical products and medical supplies

- Textile and garment products (needle detection)

With its waterproof construction and anti-interference design, this metal detector performs reliably in various industrial environments. The system's intelligent processing capabilities minimize false alarms while maintaining high detection accuracy.

Outstanding experience from start to finish. The delivery was remarkably fast and efficient, arriving well ahead of the estimated schedule, which was a pleasant surprise. The packaging was exceptionally secure and professional, ensuring the product arrived in pristine condition without any signs of damage. Regarding the quality, the construction feels robust and durable, exactly as one would expect for industrial-grade equipment. The finish and attention to detail are impressive, giving immediate confidence in its reliability and performance. The service provided by the team was equally commendable; communication was clear, prompt, and very helpful throughout the entire process. Any preliminary questions were answered thoroughly and without delay. Overall, this was a seamless transaction that exceeded expectations in terms of logistics, the apparent quality of the item, and the excellent customer support. Highly satisfactory and would not hesitate to recommend based on these aspects alone.

The delivery was incredibly fast and efficient. I was pleasantly surprised by how quickly the order arrived, especially given the current global shipping challenges. The packaging was secure and professional, ensuring the product was in perfect condition upon arrival. Regarding the quality, the detector feels robust and well-made, with a solid construction that inspires confidence in its durability for industrial use. The service provided by the team was outstanding; they were responsive and helpful throughout the entire process, answering all my preliminary questions promptly. Overall, a very smooth and satisfactory experience from start to finish. The attention to detail in both the product and the customer interaction is commendable. I would not hesitate to order from this supplier again for future needs. The entire transaction was handled with the utmost professionalism, making it a truly positive experience. This level of service is rare and greatly appreciated in today’s market. Thank you for a job well done and for making the procurement process so straightforward and reliable. It is clear that customer satisfaction is a top priority here, which is very reassuring.

Delivery was impressively swift and well-handled. The courier service provided consistent updates, and the package arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was securely packaged with no signs of damage during transit. The overall logistics experience was seamless and highly professional, making the receiving process straightforward and efficient. Regarding the item’s quality, it appears robust and well-manufactured, aligning with the descriptions provided. The construction feels durable, suitable for industrial settings, and the finish is neat without any obvious defects. It gives a strong impression of reliability and precision engineering. As for customer service, the support team was responsive and courteous in all communications. They answered queries promptly and offered clear assistance when needed, ensuring a smooth transaction from start to finish. This level of attentiveness greatly enhanced the purchasing experience. Overall, this was a very satisfactory acquisition, marked by excellent logistics, solid perceived quality, and outstanding service support. I would confidently consider this supplier for future needs based on this positive interaction.

Keenly awaiting the arrival of this critical piece of equipment, I must say the logistics process was handled with remarkable professionalism. The shipment arrived precisely within the estimated timeframe, which was a relief given our tight production schedule. The packaging was exceptionally robust and secure, clearly designed to protect sensitive industrial electronics. Every component was individually wrapped and cushioned, showing great attention to detail. Regarding the unit's quality, the initial inspection reveals a very solid and well-constructed machine. The stainless-steel housing feels durable and the overall fit and finish are impressive, exactly what one expects for a CE-certified industrial device. It has a substantial, professional heft to it. The service experience, from initial inquiry to post-delivery support, has been consistently responsive and knowledgeable. The communication was clear, and any logistical queries were addressed promptly. While I cannot yet comment on its operational performance in our line, the foundational aspects of receiving a high-quality product through an efficient and service-oriented channel have been thoroughly positive. This smooth start is crucial for integrating new equipment into a regulated environment like ours. The entire pre-commissioning experience, based purely on delivery and first impressions, instills confidence in the supplier's reliability and the product's inherent build standard.

Rapid delivery was the first thing that impressed me. The shipment arrived well ahead of the estimated schedule, which was a fantastic start. Regarding the product itself, the build quality feels exceptionally robust and professional, exactly what one would expect for industrial-grade equipment. The initial setup documentation was clear, and the unit appears to be manufactured to a very high standard. The customer service team was responsive and polite in their pre-delivery communications, confirming the order details promptly. Overall, the entire experience from ordering to unboxing was seamless and efficient. The packaging was secure and appropriate, ensuring the detector arrived in perfect condition without any signs of mishandling during transit. This level of attention to logistical detail is commendable and reflects well on the supplier. While I cannot yet comment on long-term performance in our facility, the initial physical inspection and the smooth procurement process have certainly met, and in some aspects exceeded, my expectations for such a critical piece of safety equipment. The certification markings are clearly visible and add confidence in the product’s compliance. This positive experience with the logistics and the tangible quality of the item itself provides a strong foundation for its intended application.

Prompt delivery and excellent packaging ensured the product arrived in perfect condition. The build quality feels robust and professional, exactly as described for industrial use. Customer service was responsive and helpful during the ordering process. Overall, a very satisfactory experience from start to finish. The shipping was faster than anticipated, which was a pleasant surprise. The item itself appears to be manufactured to high standards, giving confidence in its durability and performance. Any preliminary questions I had were answered quickly and courteously by the support team. This efficient service and evident product quality make the purchase highly commendable. The logistical handling was seamless, with clear communication at every stage. I am thoroughly impressed and would not hesitate to recommend this supplier based on this transaction.

Very impressed with the overall experience! The shipping was incredibly fast, arriving much sooner than expected, which was a pleasant surprise. The packaging was secure and ensured the item was well-protected during transit. In terms of quality, the product feels robust and well-made, showing excellent craftsmanship that gives me confidence in its durability. Customer service was outstanding; the team was responsive, helpful, and resolved my queries promptly with a friendly attitude. Everything from start to finish was smooth and hassle-free, making this a highly satisfying purchase. I would definitely recommend this to others based on these positive aspects.

Yikes, the shipping was incredibly fast and reliable, which made the whole process smooth and hassle-free. Your service team was super responsive and helpful, addressing all my queries promptly with a friendly attitude. The build quality feels robust and durable, exactly what I needed for industrial applications. Overall, a fantastic experience from start to finish—highly recommended for anyone seeking efficiency and top-notch support!

Fantastic experience overall! The shipping was incredibly fast and reliable, arriving well ahead of schedule without any delays. The packaging was secure and ensured the product was in perfect condition upon arrival. In terms of quality, the item feels sturdy and well-made, exceeding my expectations for durability. Customer service was outstanding; the support team was responsive and helpful, promptly addressing my inquiries with clear and friendly communication. I'm thoroughly impressed and would highly recommend this for anyone needing efficient and high-quality service.

Swift delivery and excellent packaging ensured the product arrived safely without any delays. The build quality is robust and durable, meeting high industrial standards. Superb customer service provided prompt responses and helpful assistance throughout the process, making the experience smooth and satisfactory.