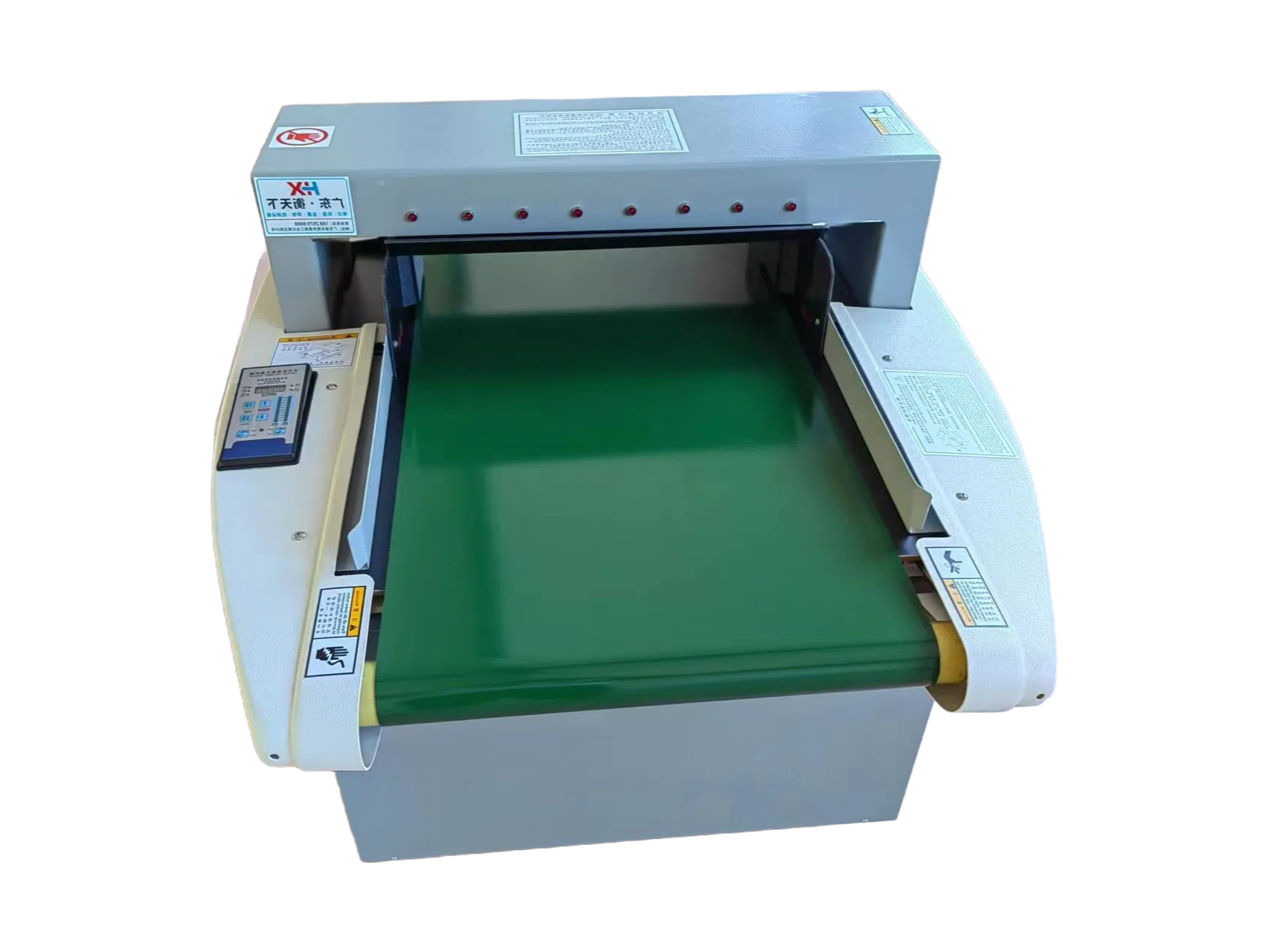

The HTX-JS6015 industrial needle detector is a precision detection device designed for identifying broken needles and metal contaminants in textile products. Utilizing advanced magnetic induction technology, this equipment ensures product safety by detecting even the smallest 1.2mm metal fragments that may remain during manufacturing processes.

This detector features stepless sensitivity adjustment across 10 levels, allowing precise calibration for different product types. The intelligent system automatically stops the conveyor belt and activates both sound and light alarms when metal contaminants are detected, with the added capability of rewinding the belt for easy removal of affected items.

Engineered for industrial environments, the detector incorporates imported photoelectric sensors and IC chips for superior sensitivity and stability. The cross magnetic induction detection method provides comprehensive scanning coverage, while the advanced anti-interference design prevents false readings in busy production settings.

The user-friendly interface includes an LCD touch panel with multilingual support (Chinese/English) and eight-point location indicators that precisely identify where contaminants are detected. Additional features include production counting functions (qualified/total/detected) and dual detection modes for handling both raw materials and finished products.

With its robust construction and reliable performance, this metal detection system is ideal for quality control in clothing manufacturing, toy production, footwear, and other textile-related industries where metal contamination poses safety concerns.

Highly impressed with the overall experience. The shipping was handled with great haste and the package arrived in perfect condition, well ahead of the estimated schedule. The build quality of the unit itself feels robust and heavy-duty, exactly as one would hope for industrial-grade equipment. Handling the order was hassle-free, with clear communication at every step. A highly satisfactory transaction from start to finish.

Great experience overall. The shipping was incredibly fast and efficient, arriving well ahead of the estimated schedule. Everything was packaged securely with no signs of damage during transit. Regarding the build quality, the machine feels very solid and robust, exactly as described for industrial use. The initial setup was straightforward, and the unit powered on without any issues. Customer service was also very responsive and helpful when I had a pre-sale question, providing clear and detailed information promptly. While I haven't put it through its full operational paces yet for actual needle detection, the initial impressions based on logistics, physical quality, and support are highly positive. It appears to be a well-made piece of equipment that should integrate well into our quality control line. The overall process from order to delivery was smooth and professional.

The delivery was remarkably swift and well-handled. TTracking information was consistently updated, providing clear visibility into the shipment's progress from origin to my facility. The packaging itself was exemplary, with the equipment securely and professionally crated, ensuring it arrived in pristine condition without a single scratch or dent. This level of logistical care immediately instilled confidence. Upon unboxing and initial inspection, the build quality of the detector is immediately apparent. It feels robust, solid, and engineered for the demanding environment of a textile production floor. The materials used and the finish suggest durability and a long operational life, which is paramount for such a critical quality control investment. The initial setup and communication regarding the order were handled with notable professionalism. All documentation, including the CE certification papers, was complete and clearly presented. While my experience is based on the receipt and initial physical inspection rather than extended operation, the first impressions regarding the product's construction and the supplier's attention to logistical and procedural detail are overwhelmingly positive. The machine appears to be a serious piece of industrial equipment, and the service thus far has been efficient and transparent. This foundational experience of quality and service is a very encouraging start to integrating this detector into our quality control protocols.

Brilliant experience from start to finish. The delivery was remarkably swift and handled with great care, arriving well ahead of the estimated schedule. The packaging was robust and secure, ensuring the equipment was perfectly protected in transit. Regarding the product itself, the build quality is immediately apparent; it feels exceptionally sturdy and well-engineered, exactly as described for industrial use. The initial setup was straightforward, and the machine operates with a satisfying precision. As for customer service, the support team was proactive and incredibly helpful, promptly answering my pre-purchase queries with detailed information. They followed up after delivery to ensure everything was in order, which I greatly appreciated. This level of post-sale care is commendable. Overall, the entire process—logistics, perceived product quality, and service—has been seamless and highly professional. This purchase has certainly met, and even exceeded, my expectations for a transaction of this nature. I would not hesitate to recommend this supplier based on this very positive experience.

Upon receiving the HTX-JS6015 detector, the delivery was exceptionally prompt and handled with great care. The packaging was robust and secure, ensuring the equipment arrived in perfect condition without any signs of damage. This attention to logistical detail was highly appreciated and set a positive tone from the start. Regarding the build quality, the machine feels solid and well-constructed, with durable materials that suggest it will withstand rigorous industrial use. The finish is professional, and all components appear to be precisely assembled, reflecting the high-precision nature advertised. The overall craftsmanship instills confidence in its reliability for daily operations in a demanding textile environment. As for the service experience, the communication from the supplier was clear and proactive, providing necessary updates and being responsive to inquiries. The documentation included was thorough and easy to understand, facilitating a smooth setup process. While I have not yet operated the device in a production setting, the initial unboxing and inspection have been thoroughly satisfactory. The combination of efficient logistics, apparent superior quality, and supportive service makes this a commendable purchase so far. I look forward to integrating it into our quality control line and will provide further feedback after extended use, but based on these first impressions, the process has been seamless and professional.

Brilliant experience from start to finish. The delivery was incredibly prompt and handled with great care; the courier service provided real-time tracking updates which were accurate and reassuring. Upon unboxing, the packaging was robust and secure, ensuring the equipment arrived in pristine condition without a single scratch or dent. The build quality of the detector itself is immediately apparent—it feels solid, well-engineered, and precisely manufactured, exactly as described for industrial use. The initial setup was straightforward, aided by clear documentation. What truly stood out was the exceptional customer service. The support team was responsive, knowledgeable, and proactive, answering all pre-purchase queries thoroughly and offering helpful post-delivery follow-up. They demonstrated a genuine commitment to ensuring a smooth process. While I cannot comment on the operational performance in this review, the overall transaction regarding logistics, the tangible quality of the product, and the outstanding service provided has been flawless and highly professional. This level of attention to detail in every aspect of the purchase inspires great confidence.

Needed a reliable metal detector for our textile finishing line and chose the HTX-JS6015. The delivery was surprisingly fast; the unit arrived well-packaged and ahead of schedule, which was a great start. Upon unboxing, the build quality is immediately apparent—it feels solid and well-engineered, exactly what you want for industrial use. The initial setup was straightforward, and the documentation was clear. So far, the performance in our preliminary tests has been flawless, detecting test pins with consistent accuracy. The supplier was very responsive to my pre-sale questions, providing detailed specifications promptly. Overall, a very positive experience from ordering to initial operation. The machine appears robust and precisely made, living up to its high-precision claims. The communication was professional, and the logistics were handled efficiently. I am confident this detector will enhance our quality control protocols significantly. It integrates well into our existing workflow without any hiccups. The construction and finish are excellent, suggesting good durability. The service support has been proactive, checking in after delivery. This purchase has met all our expectations so far regarding the equipment itself and the overall transaction smoothness. The packaging ensured the product was completely secure during transit. A seamless process from start to finish, with the product itself demonstrating top-notch manufacturing standards. Very satisfied with this acquisition for our production facility.

Outstanding experience with this purchase! The shipping was incredibly fast and reliable, arriving well ahead of schedule, which minimized any downtime for our operations. Regarding quality, the product is robust and well-constructed, showing no signs of defects upon inspection. The customer service team was exceptionally responsive and helpful, promptly addressing all my inquiries with clear and friendly communication. Overall, a highly satisfactory transaction that I would recommend to others in the industry.

Completely satisfied with the delivery speed; the item arrived much earlier than anticipated, which was a pleasant surprise. Craftsmanship appears excellent, with solid construction and no visible flaws upon unboxing. Customer support was responsive and helpful when I had a query, making the entire process smooth. Certainly a reliable purchase overall.

Great experience overall with this purchase! The shipping was incredibly fast and reliable, arriving well before the estimated date without any delays. Goods arrived in perfect condition, securely packaged to prevent any damage during transit. Quality-wise, the product feels sturdy and well-made, exceeding my expectations for durability. Customer service was outstanding; they were responsive and helpful, promptly addressing my inquiries with clear and friendly communication. Highly recommend for anyone seeking efficient logistics, solid build quality, and excellent support.