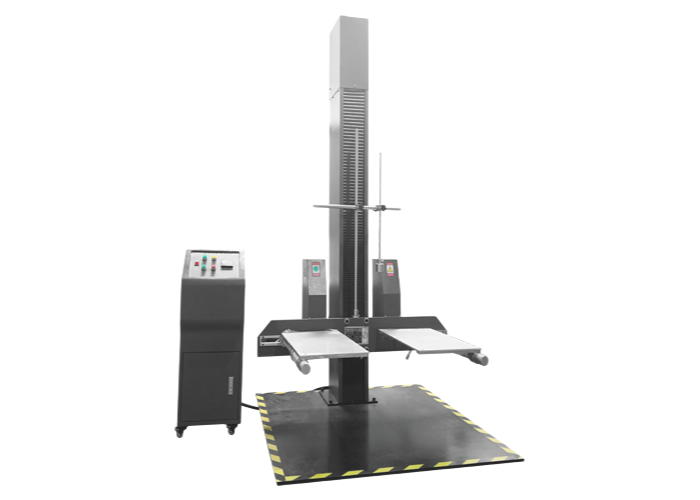

The HD-A520-1 Package Drop Testing Machine is a precision instrument designed to simulate real-world drop impacts during product transportation and handling. This equipment evaluates packaging durability by performing controlled free-fall tests from adjustable heights between 400mm to 1500mm.

Engineered for comprehensive testing, this machine can evaluate all rhombohedrons, angles and faces of packaged products. The large drop panel area (1200×1400mm) accommodates various package sizes up to 1000×1000×800mm, making it suitable for most industrial packaging requirements.

Key features include electric transmission system, digital height indicator, and computer-controlled operation. The machine complies with international standards including ISO 2248, JIS Z0202-87, and GB/T4857.5-92, ensuring reliable and standardized test results.

With a robust construction weighing 400kg, the tester maintains stability during operation. The 1/2 HP motor provides consistent performance while the AC220V power supply ensures compatibility with standard industrial power systems.

This drop tester is particularly valuable for quality control in packaging production lines, helping manufacturers optimize their packaging designs and reduce product damage during shipping. The digital display provides precise height measurement and test data recording for quality assurance documentation.