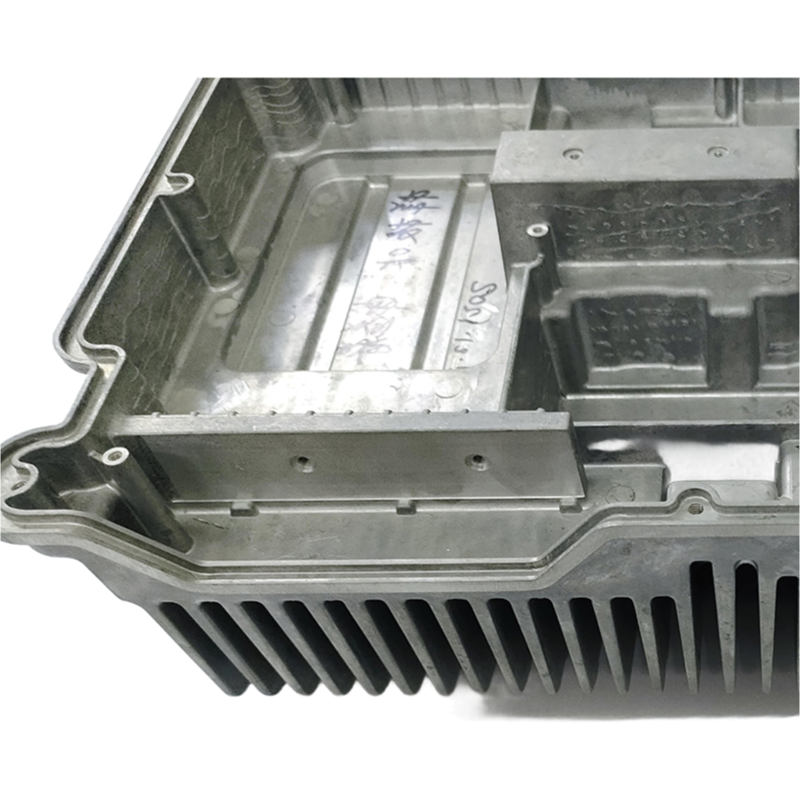

Our high pressure aluminum heat sink die casting is designed specifically for battery cases, offering excellent thermal management and durability. The product undergoes precision die casting processes to ensure dimensional accuracy and structural integrity. Available with powder coating and other surface treatments to meet various aesthetic and functional requirements.

We utilize materials such as aluminum alloys A6063, 7075, ADC12, A360, A380, and zinc alloys including zamak 3 and zamak 5. Our manufacturing capabilities include die casting, aluminum extrusion, cold forging, and CNC machining, providing a comprehensive solution for your heat sink needs.

Quality is paramount in our production process. We employ advanced testing equipment including airtightness testers, salt spray testers, X-ray flaw detectors, and more to ensure every product meets stringent standards. Our tolerance range is from +/-0.05mm to +/-0.2mm, ensuring precise fit and performance.

Surface treatment options are extensive, including paint, powder spraying, electroplating, electrophoresis, anodic oxidation, passivation, sand blasting, and screen printing. All treatments are customized to client specifications, enhancing both functionality and appearance.

We support various drawing formats such as PDF, DXF, DWG, STEP, IGS, and x-t, facilitating seamless integration into your design and production workflows. Our professional equipment includes 12 sets of die casting machines ranging from 280-1500T, 10 drilling and tapping machines, and 48 CNC processing centers, ensuring we can handle diverse and complex orders.

Post-processing services include manual and auto-machine grinding to achieve the desired finish. With over 20 years of experience, we provide one-stop design and manufacturing solutions from mold design (with free DFM) to mass production, optimizing costs at every stage.

Our quality control adheres to ISO9001 and IATF16949 standards, with full inspection before packaging. We pride ourselves on strong executive power, offering quotations within 24 hours, quick responses, and fast delivery to meet tight deadlines.

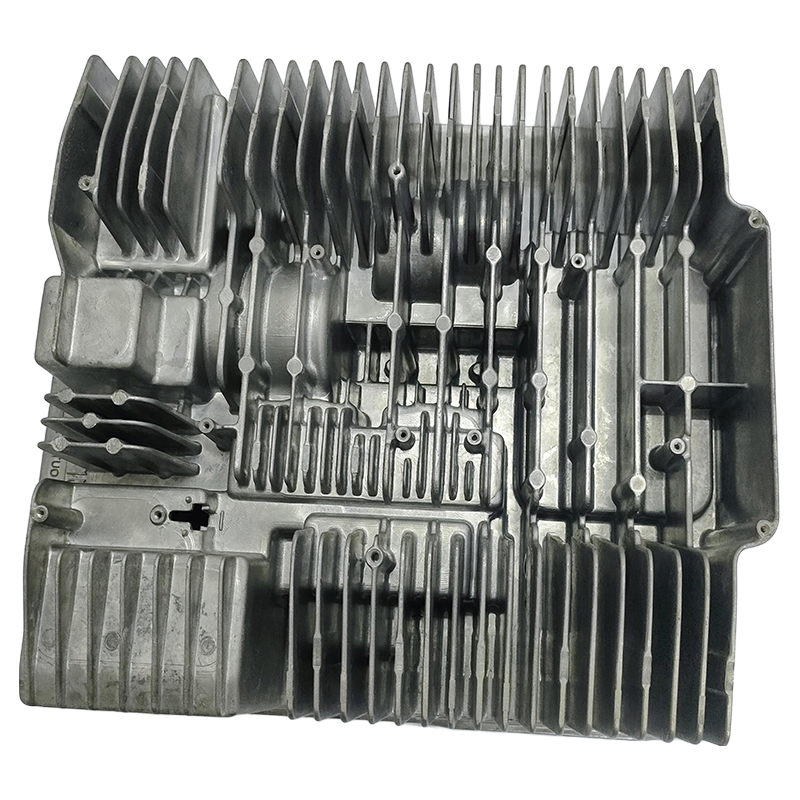

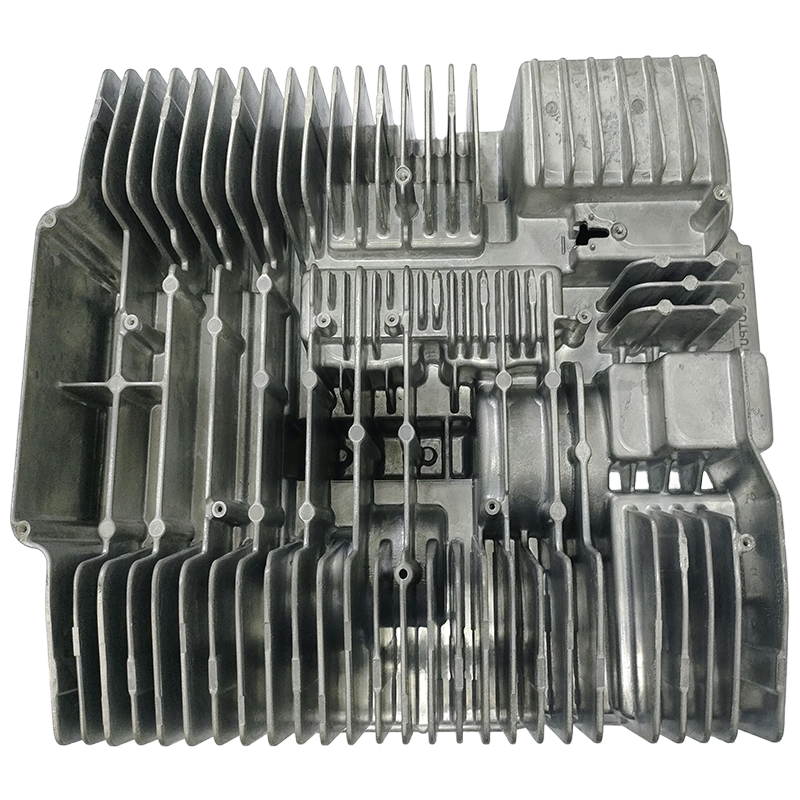

For visual reference, here are images of our products:

Rapid and reliable delivery was the first thing that impressed me. The logistics were seamless, with clear tracking updates from dispatch to arrival. The packaging was exceptionally secure, ensuring the components arrived in pristine condition without a single dent or scratch. Regarding quality, the craftsmanship is outstanding. The aluminum heat sink exhibits excellent structural integrity and a flawless powder-coated finish that appears both durable and professional. The precision of the die casting is evident, with clean edges and consistent dimensions. On the service front, the communication was prompt and helpful throughout the ordering process. Any preliminary inquiries were addressed thoroughly and courteously. The overall experience from purchase to delivery was highly efficient and satisfactory. This supplier demonstrates a strong commitment to both product excellence and customer support, making them a reliable partner for custom manufacturing needs.

Punctual delivery and secure packaging ensured the product arrived in excellent condition. The logistics team handled everything efficiently, with clear tracking updates provided throughout the shipping process. Communication was timely and professional, making the entire transaction smooth and worry-free. The quality of the aluminum heat sink is immediately apparent; it feels robust and well-constructed. The die casting appears precise, with clean edges and a consistent structure that suggests careful manufacturing. The powder coating is uniformly applied, providing a sleek, durable finish that seems perfect for battery enclosure applications. This attention to detail in the finish likely contributes to both corrosion resistance and thermal performance. Customer service was responsive and helpful from the initial inquiry to the post-delivery follow-up. They were knowledgeable about their custom manufacturing process and willing to address specific questions regarding the product’s suitability for battery cases. The overall service experience was positive, fostering confidence in the supplier. While I cannot comment on specific technical performance in an operational setting yet, the initial impressions regarding build quality, protective coating, and dimensional accuracy are highly favorable. The product appears to meet the specifications for a custom component, and the supplier’s professionalism in logistics and client support is commendable. This seems like a reliable source for specialized die-cast aluminum parts requiring a high-quality protective finish.

Beyond expectations in every aspect! The delivery was incredibly fast, arriving days earlier than estimated, which was a pleasant surprise. Packaging was secure and professional, ensuring the product arrived in perfect condition without any damage. Quality is outstanding—the finish is smooth and precise, showing excellent craftsmanship in the die casting and powder coating. Customer service was responsive and helpful, promptly answering all my inquiries with clear, friendly communication. Overall, a seamless experience from order to receipt, making me feel confident in choosing this supplier. Highly recommended for anyone needing reliable custom manufacturing solutions.

Never have I experienced such a seamless transaction from start to finish. The delivery was incredibly fast, arriving well ahead of schedule, which was a pleasant surprise. No delays or issues with the shipping process at all. As for the quality, it's absolutely top-notch; the finish is smooth and durable, showing no signs of defects. The customer service team was very responsive and helpful, answering all my queries promptly and professionally. Overall, a fantastic experience that I would highly recommend to others.

Excellent delivery speed and careful packaging ensured the items arrived safely without any delays. The build quality is robust and durable, with a smooth finish that meets high standards. Customer support was responsive and helpful throughout the process, addressing inquiries promptly. Everything was handled professionally from start to finish.