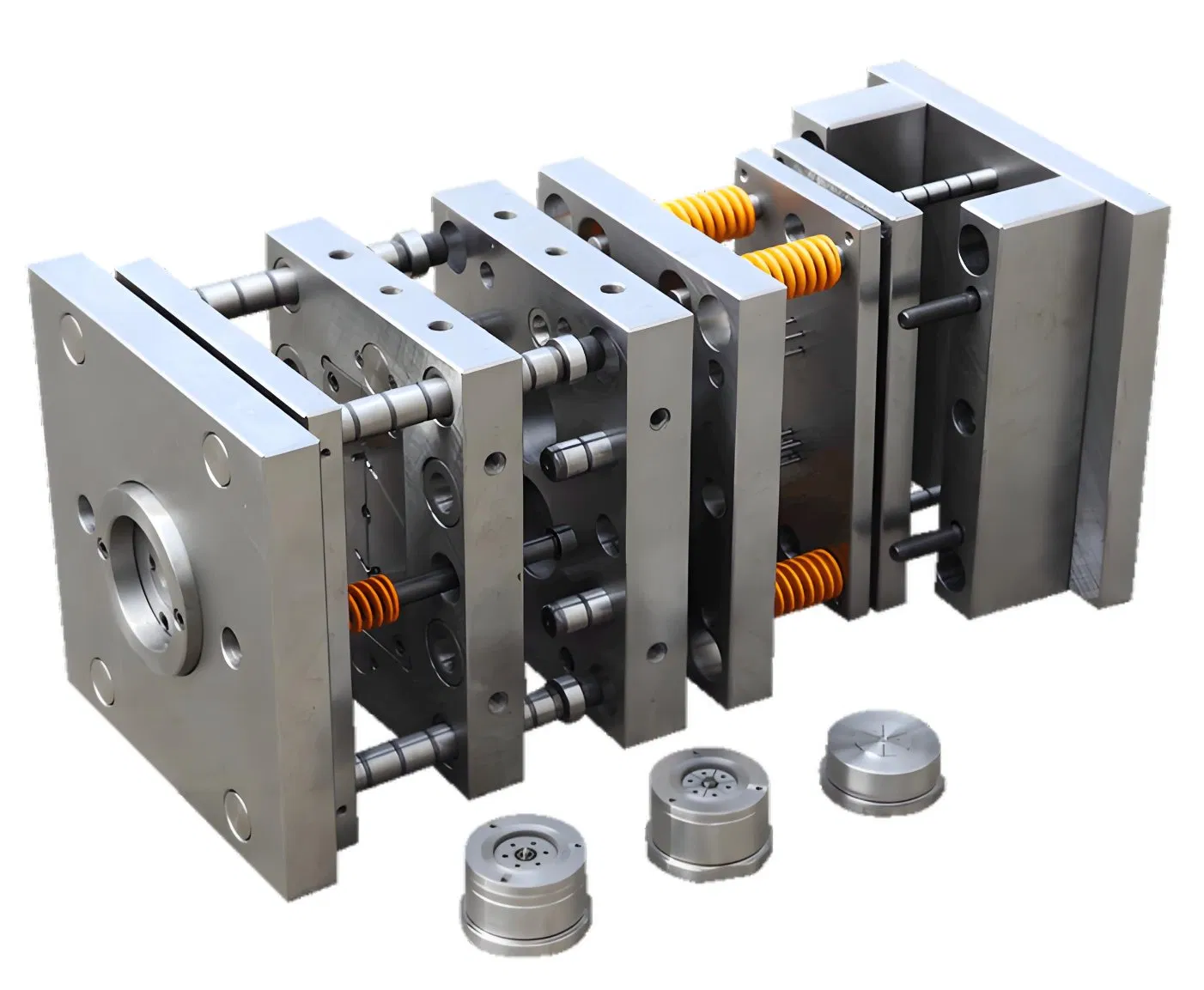

Our plastic injection molding service specializes in manufacturing high precision plastic components for various industries including medical, automotive, electronics and household applications. With advanced molding technology and strict quality control, we deliver products with exceptional dimensional accuracy and surface finish.

We utilize premium mold materials including 45#, P20, H13, 718, and NAK80 to ensure mold longevity from 50,000 to 1,000,000 shots. Our production materials cover a wide range of engineering plastics such as PP, ABS, PC, PET, PVC, and PA to meet different application requirements.

Our manufacturing process features precise temperature control and pressure monitoring to guarantee consistent product quality. We offer various surface treatment options including electroplating and spray painting to enhance both functionality and aesthetics of the final products.

With professional design support using ProE/UG/CAD software, we can develop custom solutions based on your specific requirements. Our quality control team utilizes advanced inspection equipment to verify dimensional accuracy and material properties.

We maintain strict compliance with international standards including RoHS and ISO9001:2015 certification. Our production facility is equipped with modern injection molding machines capable of handling both small prototype runs and large volume production orders.

Vastly impressed with the overall experience regarding this bulk order of plastic injection molded pieces. The logistics were handled with exceptional care and efficiency. From the initial shipping notification to the final delivery, every step was transparent and timely. The package arrived well ahead of the estimated schedule, which was a pleasant surprise and greatly assisted our project timeline. The packaging itself was robust and secure, ensuring all components arrived in pristine condition without a single item damaged or misplaced. This level of logistical precision is commendable and reflects a highly organized operation. Regarding quality, the molded pieces are outstanding. They exhibit excellent craftsmanship, with sharp, clean edges and a consistent finish across the entire batch. The precision is evident, meeting the exact specifications required for our sensor and automation equipment. The material feels durable and suitable for industrial applications, showing no signs of warping or imperfections. It is clear that the manufacturing process is controlled with high standards, resulting in components that inspire confidence for integration into our systems. The service provided throughout was equally remarkable. Communication was proactive, clear, and professional from the initial inquiry to post-delivery follow-up. All questions were answered promptly and thoroughly, demonstrating deep expertise in custom plastic parts and injection molding. The team was accommodating and showed a genuine commitment to fulfilling our requirements as an OEM partner. This collaborative and responsive approach made the entire procurement process smooth and stress-free. In summary, the combination of flawless logistics, superior quality, and exemplary service makes this supplier a top-tier choice for precision plastic components. This order has fully met our expectations for a critical project, and we are highly satisfied with the partnership. We look forward to future collaborations and confidently recommend their services for anyone in need of reliable custom plastic molding solutions.

Came across this company for our bulk order of plastic injection molded pieces, and the experience was commendable. The logistics were handled smoothly, with timely updates and on-schedule delivery that minimized our project downtime. Quality-wise, the precision plastic components met our specifications without any defects, showcasing excellent craftsmanship. Customer service was responsive and professional, addressing all our queries promptly. Overall, a reliable choice for custom plastic parts in sensor and automation equipment.

My experience with this order was excellent overall. The logistics were handled smoothly, with the items arriving ahead of schedule and in perfect condition, which minimized any delays in our project timeline. The quality of the plastic molded pieces is outstanding; they are durable, well-finished, and meet the high standards required for sensor and automation equipment without any visible defects. Customer service was responsive and professional, promptly addressing my inquiries and providing clear updates throughout the process. I highly recommend this supplier for their reliability and attention to detail.