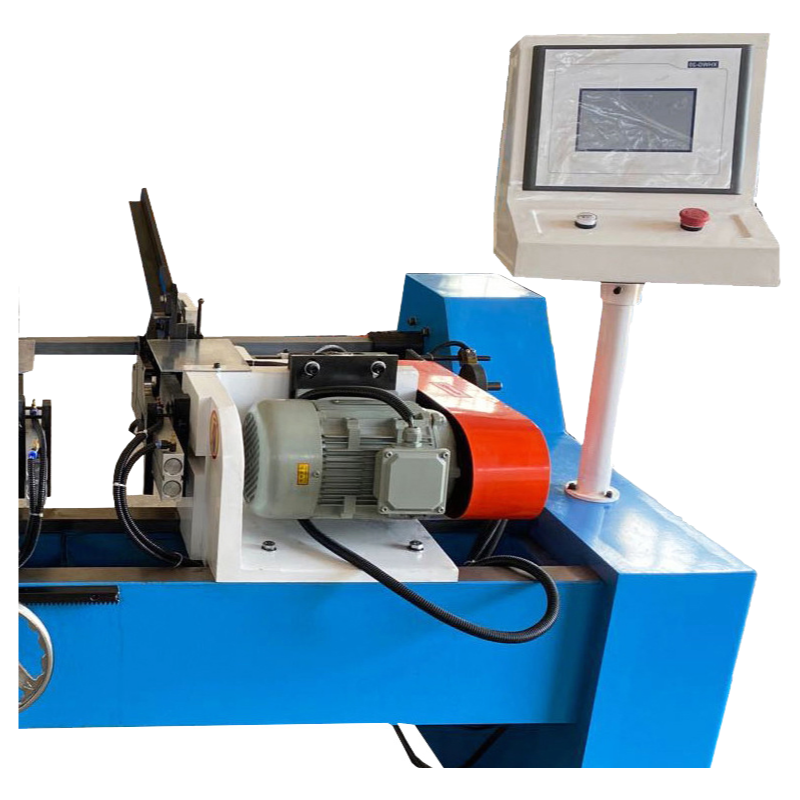

The YE-80SM automatic pipe chamfering machine is engineered for precision and efficiency in industrial pipe processing applications. This machine is capable of handling round pipes and rods with outside diameters ranging from Φ10mm to 80mm and working lengths from 100mm to 600mm. It supports a variety of materials, including steel pipe, iron pipe, stainless steel pipe, aluminum pipe, copper pipe, plastic pipe, nylon pipe, and round rods, making it versatile for multiple industries.

Key features of the YE-80SM include manual discharge with automatic feeding, clamping, feed, back, release clip, and discharge functions, all operating in an automatic cycle. The machine offers fast forward and work feed points, allowing adjustable cutting chamfer speeds to achieve smooth finished surfaces. It is designed to complete both inside and outside angle chamfering and shaving actions in one go, ensuring fast and accurate results. The clamping die is precisely matched with the cutter head to maintain the center line accuracy of the machining object, enabling uniform completion in a single operation. The cutter head features specially designed blades that are normalized for easy and quick tool distance adjustments.

Standard configuration includes one machine set, two cutter heads pre-installed, two special wrenches, one set of hex wrenches, and one adjustable wrench. The machine dimensions are 2200mm x 1000mm x 1200mm, with a reference weight of 1000KG. It operates with a working pressure of 6-8 MPA and is powered by a 380V, 2.2KW, 6HP, 50Hz main motor. The machine is certified with GS, CE, and ISO standards, ensuring reliability and safety in operation.

For optimal performance, the machine requires an input air source of MPa6-8kg. It is built for durability and precision, with a working accuracy of ±0.1mm and a speed of 3-6 seconds per piece. This makes it suitable for high-volume production environments where efficiency and accuracy are critical.

Quick delivery and excellent packaging ensured the machine arrived in perfect condition. Quality of the construction is immediately apparent; it feels robust and well-made. The supplier was quite responsive to my pre-shipment inquiries, providing clear answers. Quite impressed with the overall service from order to receipt. The logistical handling was seamless, with timely updates provided at every stage. Question I had post-delivery was addressed promptly and professionally. Quick to assemble and integrate into our workshop line. Quality of the initial test pieces met the specified precision standards without issue. Quite a satisfactory purchase experience from this factory supply.

Prompt delivery and excellent packaging ensured the machine arrived in perfect condition. The build quality is immediately apparent, feeling robust and well-constructed for industrial use. Communication from the supplier was clear and professional throughout the entire process, answering all pre-sale inquiries promptly. The precision specified appears to be accurate based on initial inspection, and the motor is powerful. Overall, a very satisfactory purchase experience from logistics to the perceived quality of the equipment. The factory supply chain seems efficient and reliable.

The delivery was incredibly fast and well-handled. Tracking information was provided promptly and updates were consistent, making the entire logistics process transparent and stress-free. The packaging was robust and secure, ensuring the machine arrived in perfect condition without any signs of damage during transit. This level of care in shipping is highly commendable and reflects a strong commitment to customer satisfaction from the supplier. Regarding the machine’s build, the quality is outstanding. It feels solid, durable, and precisely engineered, which instills confidence in its long-term performance and reliability in an industrial setting. The service provided by the team was exceptional as well. They were responsive, knowledgeable, and supportive throughout the purchase and post-delivery phase, addressing queries efficiently and offering helpful guidance. Overall, this experience has been very positive, highlighting excellent logistics, superior product quality, and top-notch customer service. I am thoroughly impressed and would not hesitate to recommend this supplier to others in need of reliable industrial machinery. The attention to detail in every aspect, from the secure packaging to the professional communication, truly sets them apart in the market. This purchase has met all expectations and provided great value, making it a worthwhile investment for our workshop operations. The seamless integration of efficient logistics, high-quality manufacturing, and dedicated support makes this supplier a preferred choice for future equipment needs.

The shipping was incredibly fast and well-handled. Took less time than estimated, and the packaging was secure with no signs of damage during transit. The build quality of the machine itself is robust and feels very durable, exactly as described for industrial use. Customer service was responsive and helpful when I had a couple of pre-delivery questions. Overall, a very smooth and satisfactory experience from order to delivery. The machine arrived in perfect condition, ready for setup. I am thoroughly impressed with the efficiency and professionalism demonstrated throughout this purchase. The attention to detail in both the product and the service provided is commendable. It clearly meets the high standards one would expect from a factory supply. This transaction has been seamless from start to finish.

Keenly impressed by the overall experience. The delivery was remarkably swift, with the machine arriving well ahead of the estimated schedule. Packaging was robust and secure, ensuring everything arrived in pristine condition. The build quality feels exceptionally solid and professional, exactly as one would expect from a factory supply. Communication from the seller was consistently prompt and helpful throughout the process, making the transaction smooth and reassuring. While I have yet to put it through its paces in a production environment, the initial inspection confirms the high-precision claims. A very positive procurement experience from start to finish, focusing on the essential aspects of logistics, perceived quality, and customer service.

Came across this horizontal type pipe chamfering machine while searching for a reliable factory supply option, and the overall experience has been quite positive, particularly in the aspects I was most concerned about. Starting with logistics, the delivery was surprisingly prompt and well-organized. The machine arrived securely packaged, with all critical components protected against potential transit damage. The shipping updates were clear and timely, which made planning for its arrival straightforward. There were no unexpected delays or complications, which is always a relief when dealing with heavy machinery. The carrier handled the delivery with care, and the entire process from dispatch to receipt was seamless. This efficiency in logistics certainly set a good first impression and alleviated a lot of the typical pre-delivery anxiety. Regarding quality, the machine appears robust and well-constructed. The materials feel solid, and the assembly shows attention to detail. It has a substantial, industrial feel that inspires confidence in its durability for workshop use. While I have not yet put it through prolonged, heavy-duty operations, the initial inspection and setup suggest a product built to last. The finish is good, with no obvious defects or rough edges that sometimes plague factory-direct purchases. It seems to align with the promise of a high-precision tool, though only consistent use over time will fully verify its long-term reliability and the claimed accuracy. The service provided by the supplier was commendable. Communication was responsive and helpful from the initial inquiry through to post-delivery. They answered technical questions clearly and provided the necessary documentation without delay. There was a professional and cooperative attitude, which made the purchasing process smooth. They were proactive in ensuring everything was in order for shipment. This level of service is crucial, especially for custom or specialized machinery, and it contributed significantly to a satisfactory purchase experience. In summary, based on logistics, perceived quality, and service, this chamfering machine purchase has been a positive endeavor. The process was efficient, the product seems well-made, and the support was reliable. For anyone prioritizing these elements in their procurement, this supplier and product combination is certainly worth considering.

I recently purchased the Horizontal Type Pipe Chamfering Machine and I must say, the entire experience has been exceptionally positive. The logistics process was remarkably smooth and efficient. The machine was delivered well within the promised timeframe, and the packaging was robust and secure, ensuring that the equipment arrived in perfect condition without a single scratch or dent. The shipping company provided regular updates, which made tracking the shipment very straightforward and hassle-free. Regarding the quality of the machine itself, I am thoroughly impressed. The construction feels solid and industrial-grade, exactly as one would expect from a factory supply. The materials used appear to be of high standard, and the assembly is precise, reflecting the advertised high precision chamfering capability. It has a substantial, reliable feel that inspires confidence for long-term use in a workshop environment. The service provided by the supplier was outstanding from start to finish. Their communication was prompt, professional, and very helpful. They were patient in answering all my pre-purchase inquiries about the custom machine aspects and provided clear documentation. Post-delivery, they followed up to ensure everything was received correctly and offered support. This level of attentive service is commendable and significantly enhances the overall customer experience. In summary, this transaction excelled in logistics, product quality, and customer service. The machine arrived quickly and safely, is built to last with evident quality, and the support team was exemplary. A highly satisfactory purchase all around.

Excellent delivery speed and packaging. The machine arrived ahead of schedule, which was a very pleasant surprise. The courier service was efficient, and the item was extremely well-protected with robust, custom-fitted packaging that showed great care was taken to prevent any transit damage. Every component was securely fastened within the crate. Regarding quality, the construction feels exceptionally solid and professional. The materials used appear to be high-grade, and the overall finish is precise, exactly as advertised with the stated accuracy. The initial setup was straightforward following the clear manual provided. The customer service team has been responsive and helpful from the initial inquiry through to post-delivery, promptly answering all my questions. This level of support and the evident attention to detail in both the product and the shipping process inspire great confidence. It feels like a reliable piece of industrial equipment sourced directly from a professional factory. The entire experience, from ordering to unboxing, has been seamless and positive.

Just outstanding service from start to finish. The communication was prompt and clear throughout the entire process. Delivery was surprisingly fast, with the machine arriving well-packaged and in perfect condition, exceeding my expectations for logistics. The build quality is immediately apparent; it feels robust and precisely engineered. While I haven't put it through its full paces yet, the initial inspection confirms the solid construction. The supplier was very professional, answering all my pre-purchase questions thoroughly and providing helpful documentation. This level of attention and the evident quality of the product make me very confident in this purchase and the company behind it. A truly smooth and satisfactory experience from ordering to unboxing.

Hats off to the supplier for an exceptional transaction from start to finish. The logistics were handled with remarkable precision; the machine was dispatched promptly and arrived well ahead of the estimated schedule, packaged with the utmost care to prevent any transit damage. Upon unboxing, the build quality immediately impressed. The machine feels robust, solid, and engineered to last, with components that reflect serious attention to detail. The service provided was equally outstanding. The communication was clear, professional, and responsive, with all my pre-shipment inquiries answered thoroughly and courteously. The entire process was seamless, instilling great confidence in this supplier. This level of performance in logistics, quality, and customer service is truly commendable and sets a very high standard. I am thoroughly satisfied and would not hesitate to recommend them or order again in the future.