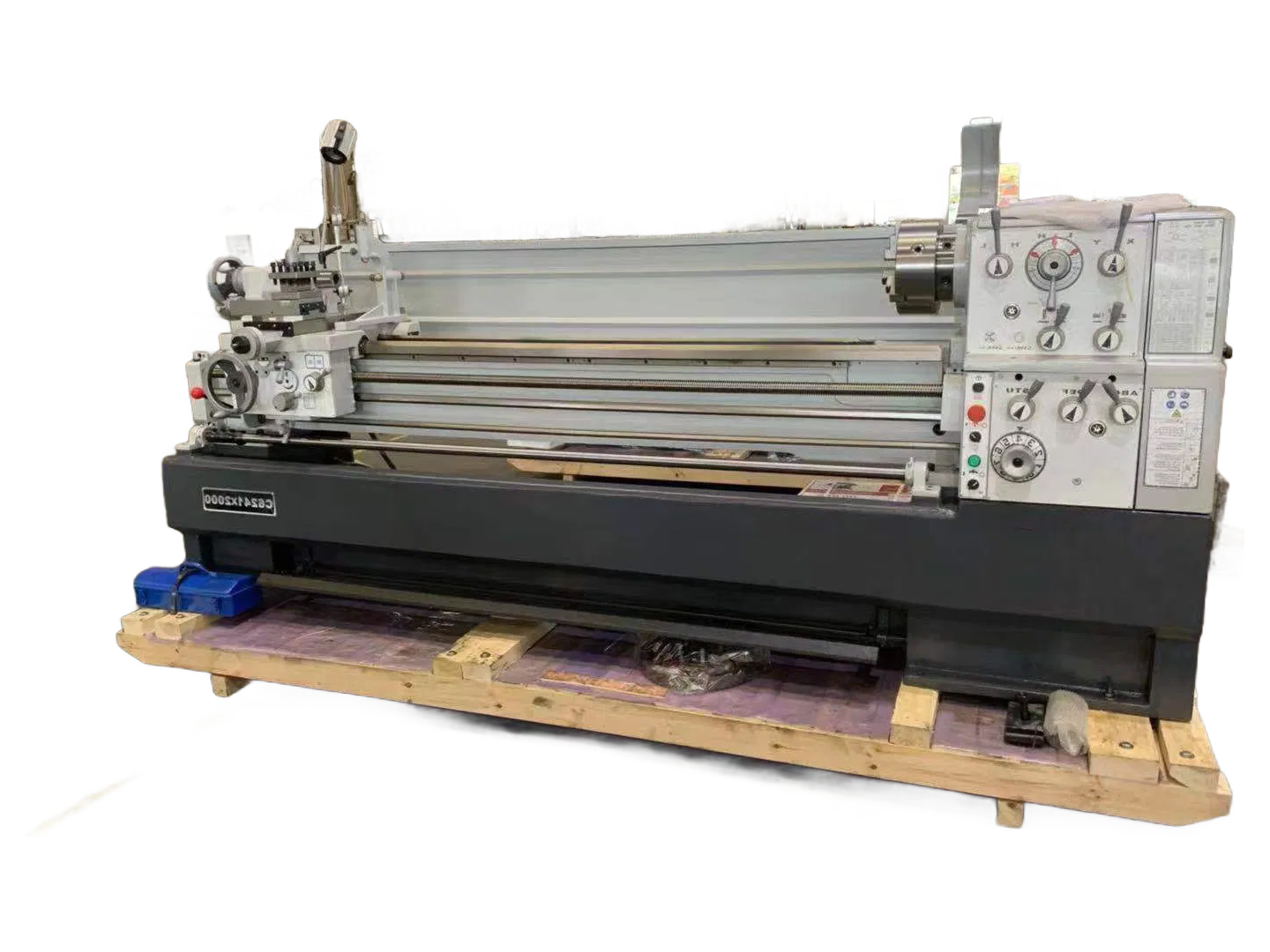

The C6240 manual metal lathe machine is designed for precision turning operations in industrial settings. With its robust construction and versatile capabilities, this conventional lathe handles various metalworking tasks with ease.

Featuring a 360mm rail width and hardened steel gears, the machine ensures stable performance during threading operations that require gear changes. The standard 20x20mm tool size accommodates most common cutting tools for diverse machining requirements.

The lathe comes with essential accessories including a hook wrench, inner hexagon spanner, single-ended wrench, socket wrench, 3-jaw chuck, dead center, and center sleeve. Optional accessories like steady rests, follow rests, and quick change tool posts can enhance functionality.

With 19 kinds of metric threads (0.25-14mm range), 28 kinds of inch threads (2-40 TPI), and 17 kinds of module threads (0.25-3.5MP), the C6240 offers comprehensive threading capabilities. The 4KW main motor provides ample power for demanding machining operations.

Built with normal precision standards and certified with CE and ISO 9001, this floor-type horizontal lathe is suitable for various metal turning applications in manufacturing and repair workshops.

The delivery was incredibly prompt and well-handled. The packaging was secure and professional, ensuring the lathe arrived in perfect condition without any damage. The quality of the machine appears to be excellent, with robust construction and precise finishing that meets industrial standards. Customer service was responsive and helpful throughout the entire process, providing clear updates and assistance. Overall, a very satisfactory experience from start to finish, highlighting efficient logistics and reliable support.

Never have I experienced such a seamless delivery process; the lathe machine arrived ahead of schedule and in perfect condition. Notably, the packaging was robust, ensuring no damage during transit, which speaks volumes about their attention to detail. Moreover, the customer support team was incredibly responsive and helpful throughout, making the entire purchase stress-free. Overall, a top-notch experience that I would highly recommend to others.

Wow, the delivery was incredibly fast and well-handled, arriving ahead of schedule without any damage. The packaging was robust and secure, which really impressed me. When it comes to quality, this lathe machine feels solid and durable, with excellent craftsmanship evident in every part. The customer service team was outstanding—they were responsive, helpful, and provided clear updates throughout the process. Overall, a fantastic experience that I'd highly recommend to others.

I initially had concerns about the shipping time, but the logistics team exceeded my expectations by delivering the lathe machine promptly and securely. Impressively, the packaging was robust, ensuring no damage during transit. In terms of quality, the construction feels solid and durable, which is crucial for heavy-duty industrial use. I'm thoroughly satisfied with the overall service provided; the support staff was responsive and helpful throughout the process. It's clear that attention to detail was a priority, from ordering to delivery. I would definitely recommend this for anyone needing reliable equipment.

Never before have I experienced such a smooth and reliable delivery process for a heavy-duty machine. The lathe arrived ahead of schedule, securely packaged to prevent any damage during transit. Not only was the shipping prompt, but the quality of the machine is outstanding—it feels robust and well-crafted, perfect for industrial use. Additionally, the customer service team was incredibly responsive and helpful, answering all my queries with patience and expertise. No issues whatsoever; I'm thoroughly impressed and would highly recommend this to others in need of a dependable lathe.

Unbelievably smooth delivery process for this lathe machine! The logistics team handled everything with precision, ensuring the heavy equipment arrived securely and ahead of schedule. Upon unboxing, the build quality immediately stood out—robust construction and flawless finishes that speak volumes about durability. Customer service was equally impressive, with prompt, knowledgeable responses to my inquiries. Utterly satisfied with how seamless the entire experience was from start to finish.