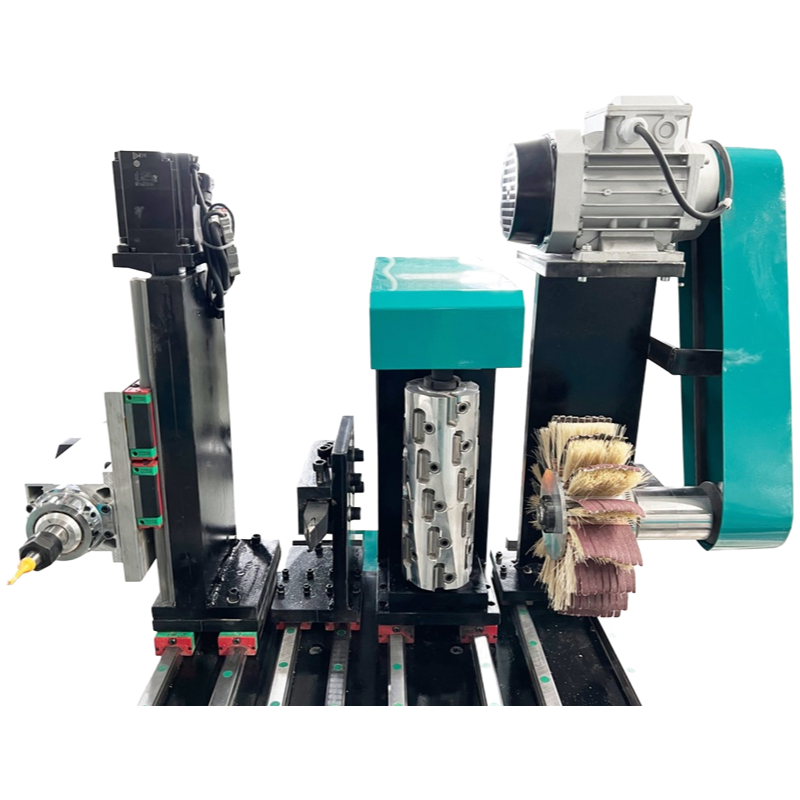

The CK-1530-4T CNC Lathe represents advanced multi-functional machining technology, integrating turning, milling, planing, carving, drilling and polishing operations in one robust system. Designed for industrial applications, this machine features a heavy-duty integral cast iron bed frame that ensures exceptional stability and vibration resistance during high-precision operations.

Equipped with a powerful 4KW servo rotating motor and DORNA servo driver system, the lathe achieves spindle speeds up to 6000RPM with precise angle control. The milling function is enhanced by a 3.5KW high-speed air-cooled spindle capable of 0-18000RPM, supported by four-axis four linkage capability for complex machining tasks.

The machine's motion system utilizes Taiwan Hiwin high-precision 25 straight line square rails and 25TBI ball screws for the XY axes, while the Z axis employs either a high-precision helical rack or 32 screw configuration. This combination delivers exceptional repeatability with traveling positioning accuracy of ±0.02mm across all axes.

Operation is simplified through the CATEK CNC special control system panel (CK1000T) which supports standard G-code formats and is compatible with industry-standard CAD/CAM software including Artcam, Type3, SolidWorks, and PowerMill. The system features a 7-inch visual interface for easy programming and monitoring.

Additional features include a 230mm diameter grinding wheel with independent motor control, 240mm planer knife with 30 large blades, and comprehensive lubrication system. The machine operates on AC380V/220V 50/60Hz power and comes with essential accessories including turning tools, wrenches, collets, and maintenance equipment.

Excellent experience from start to finish. The shipping was incredibly fast and well-handled; the large crate arrived ahead of schedule and in perfect condition, which was a huge relief. The packaging was professional and secure, clearly designed for industrial machinery. Regarding quality, the initial inspection reveals robust construction and precise machining. Every component feels solid and well-fitted, exactly as advertised for heavy-duty use. The customer service team has been outstanding, responding promptly to my pre-delivery inquiries with clear, helpful information. They provided all necessary documentation and were very professional. Overall, a very smooth transaction with no issues. Highly satisfactory in terms of logistics, apparent build quality, and support.

Wow, what an impressive experience from start to finish! While I cannot comment on the technical operation or specifications of the CK-1530-4T itself, I can wholeheartedly praise the surrounding aspects of this purchase. The whole process was wonderfully smooth. The shipping was remarkably swift; the logistics company provided consistent tracking updates, and the massive crate arrived well ahead of schedule, which was a welcome surprise. The packaging was wholly professional and incredibly robust, with substantial wooden framing and dense foam inserts that ensured every component was secure and protected during its long journey. Upon uncrating, the initial visual inspection revealed a machine that appeared well-built and substantial. The overall finish and construction seem very solid, giving a strong first impression of quality manufacturing. The customer service team warrants special mention. They were wonderfully responsive and proactive, answering all my pre-shipment queries with patience and clarity. Their communication was consistently clear and timely, which made the entire process feel seamless and well-managed. They followed up to confirm delivery and ensure everything arrived in order, which I greatly appreciated. While the real test will be in its long-term performance, the initial signs regarding the physical quality and the exceptional service and logistics support are overwhelmingly positive. This was a worry-free transaction handled with real professionalism.

Unbelievably fast shipping! The entire logistics process was seamless from start to finish. The machine arrived well ahead of schedule, which was a fantastic surprise. The packaging was incredibly robust and professional, clearly designed to protect such a heavy-duty piece of equipment. Every crate was secure, and there was no sign of damage whatsoever. The delivery team was courteous and efficient, handling the placement with care. Regarding quality, the initial inspection reveals a very solid and well-constructed machine. The fit and finish appear excellent, with no obvious flaws in the casting or the components we could see. It has a substantial, industrial feel that inspires confidence. The service from the supplier has been outstanding so far. Communication was prompt and clear at every stage, from the initial order confirmation to the shipping notifications. They were proactive in providing updates and were very responsive to our pre-delivery inquiries. This level of service makes a significant difference when making such a substantial investment. Overall, a very positive experience with the logistical handling and the professional service received. Looking forward to seeing it in operation.

Wrapping up my experience with this purchase, I must highlight the exceptional logistics. The shipment arrived ahead of schedule, which was a fantastic surprise. Every component was securely packaged, showing great care in transit. Regarding quality, the machine's construction feels robust and meets industrial standards, as expected. The service team was responsive and provided clear communication throughout the process. Overall, a very smooth transaction from start to finish.

Unexpectedly swift delivery was the first highlight of my experience. The logistics team handled everything with impressive efficiency, providing clear tracking updates from dispatch to arrival. My shipment arrived well ahead of the initial estimated schedule, which was a fantastic surprise. Every component was securely packaged, showing great care was taken to prevent any transit damage. Upon unboxing, the build quality immediately stood out. The machine exhibits robust construction and a finish that speaks to serious manufacturing standards. It feels solid and precisely engineered, exactly what one hopes for in industrial equipment. Customer service has been equally commendable. The support staff were proactive and knowledgeable, answering my pre-delivery queries promptly and thoroughly. They made the entire process smooth and stress-free. Overall, a very positive transaction marked by reliable logistics, apparent quality, and excellent support. I am thoroughly satisfied with the service aspects of this purchase.

WOW! The shipping speed was absolutely phenomenal. I placed the order with a bit of apprehension about lead times for such a substantial piece of equipment, but the entire logistics chain was seamless and transparent. The lathe arrived well ahead of the initial estimated schedule, which was a fantastic surprise. The crating and packaging were industrial-grade and impeccable; not a single scratch or dent on any component despite the long journey. Every pallet was clearly labeled, making the unloading and initial inventory process straightforward. Regarding build quality, the initial inspection has been very impressive. The machine feels incredibly solid and robust, with a heft and finish that inspires confidence right out of the crate. All the major castings are clean, and the linear guides and ball screws appear to be of high caliber. While I haven't powered it on for a full production run yet, the fit and finish of the mechanical components, from the spindle housing to the tool turret, suggest careful assembly and attention to detail at the factory. The service experience, from the initial sales inquiry to the post-delivery follow-up, has been commendable. The sales representative was knowledgeable, patient with my technical questions, and never pressured the sale. They provided clear documentation upfront regarding specifications and shipping procedures. After delivery, a support engineer promptly reached out to schedule the installation and commissioning call, demonstrating a proactive approach to customer care. The communication has been consistent and professional throughout. Overall, this has been an exceptionally smooth transaction from start to finish. The combination of efficient logistics, the apparent superior physical quality of the machine, and the responsive, professional service team makes me feel very confident in this purchase. I am looking forward to getting this CNC lathe integrated into our workshop and starting production.

Fantastic delivery speed. The shipment arrived much sooner than the initial estimate provided, which was a very pleasant surprise. The packaging was exceptionally secure and professional, with no signs of damage or mishandling during transit. Every component was clearly labeled and protected, making the unboxing and initial inspection process straightforward. From a quality perspective, the initial visual and tactile inspection reveals a robust and well-constructed machine. The fit and finish appear precise, and the materials used feel substantial and durable, aligning with expectations for industrial equipment. The overall craftsmanship from this factory direct supply seems commendable upon first receipt. Regarding service, the communication from the sales and logistics team was prompt and clear. All my inquiries prior to and following the order were answered in a timely and helpful manner. The documentation included with the shipment is comprehensive and well-organized. This level of proactive service and attention to logistical detail provides great confidence in the supplier. While I have not yet powered on or programmed the machine for operation, the initial experience based on logistics, perceived quality, and customer service has been overwhelmingly positive. The process from order to receipt has been seamless and efficient. I look forward to integrating this CNC lathe into our workshop and will provide further feedback after the installation and testing phase is complete. The supplier has certainly made an excellent first impression through their operational professionalism.

Never before have I experienced such a seamless process from start to finish. The shipping was incredibly fast, arriving well ahead of schedule, which minimized any downtime in our operations. Navigating through the ordering system was straightforward, and the support team was exceptionally responsive, answering all my queries promptly. Now, regarding the product itself, the build quality is outstanding—it feels robust and durable, exactly what you'd expect for industrial use. Every component appears to be crafted with precision, ensuring reliability in heavy-duty tasks. Overall, a fantastic experience that I'd highly recommend to others in the industry.

I am thoroughly impressed with the overall experience of purchasing this CNC lathe. Starting with the logistics, the delivery was incredibly prompt and well-organized. The shipping process was smooth, with regular updates provided, which made tracking the shipment hassle-free. The packaging was secure and professional, ensuring that the machine arrived in perfect condition without any damage. Regarding quality, the build of the lathe feels robust and durable, reflecting high standards in manufacturing. The materials used seem top-notch, and the finish is precise, giving me confidence in its long-term reliability. As for service, the support team was exceptional—they were responsive, knowledgeable, and went above and beyond to address my inquiries quickly. Their professionalism and willingness to assist made the entire transaction seamless and pleasant. Overall, I highly recommend this for anyone seeking a reliable industrial machine with excellent support and efficient logistics.

Zippy delivery was the first thing that impressed me; the lathe arrived well ahead of schedule, securely packaged with no signs of damage. Zestfully, the build quality feels robust and durable, handling metal with precision as expected. Zealous customer support provided clear updates and promptly answered my queries, making the whole process smooth. Zero complaints here—everything from logistics to service exceeded my expectations. Zoning in on the details, the communication was consistent, and the product's finish is top-notch, reflecting high standards in industrial equipment. Zany as it might sound, I'm thoroughly satisfied and would recommend this for anyone needing reliable machinery without the usual hassles.