Enameled flat wire is manufactured using oxygen-free copper or electrical aluminum rods, which are drawn or extruded through specification molds. This product is primarily utilized in the windings of electrical equipment such as transformers and reactors. Based on the type of insulating paint applied, it is categorized into six main classes: 120 polyvinyl acetal/self-adhesive polyvinyl acetal enameled copper (aluminum) flat wires (QQ/QQN), 130 polyester enameled flat wires (QZ), 155 modified polyester enameled flat wires (QZG), 180 polyester imide enameled copper (aluminum) flat wires (QZY), 200 polyester imide/polyamide-imide composite enameled copper (aluminum) flat wires (Q(ZY/XY)), and 220 polyamide imide enameled copper (aluminum) wires (QXY).

The conductor material for soft copper flat wire adheres to GB5584.2-2009 standards, with a resistivity of ≤0.017241 Ω·mm²/m at 20°C, accommodating varying mechanical strength requirements. Similarly, soft aluminum flat wire complies with GB5584.3-2009, featuring a resistivity of ≤0.02801 Ω·mm²/m at 20°C. Insulation options include thin film ranging from 0.06 to 0.11 mm or thick film from 0.12 to 0.17 mm, depending on specific needs. For hot adhesive enameled flat wire, the self-adhesive layer typically measures between 0.03 and 0.06 mm in thickness, monitored using a dielectric loss meter for precision.

Production scope covers conductor thickness (a) from 0.80 to 5.60 mm and conductor width (b) from 2.00 to 16.00 mm, with a conductor width ratio of up to 20:1. Technical parameters vary by enameled wire category, each with distinct thermal levels, performances, and standards. For instance, polyvinyl acetal/self-adhesive acetal wires (QQ/QQN) offer excellent resistance to transformer oil, scratch resistance, flexibility, adhesion, and hydrolysis resistance, conforming to GB/T 7095.2-2008 and IEC 60317-18:2004. Other categories like polyester (QZ), modified polyester (QZ(G)), polyester imide (QZY), polyester imide/polyamide-imide composite (Q(ZY/XY)), and polyamide imide (QXY) provide high mechanical strength, good electrical performance, solvent resistance, and heat resistance, adhering to relevant GB and IEC standards.

Model names and production specifications include QQB120 for acetal/self-adhesive acetal, QZB130 for polyester, QZ(G)B155 for modified polyester, QZYB180 for polyester imide, QYB220 for polyamide imide, and Q(ZY/XY)B200 for composite layers, all with conductor dimensions a: 0.80-5.60 mm and b: 2.00-16.00 mm. Paint film insulation is graded into Grade 1 (0.06≤δ≤0.11 mm) and Grade 2 (0.12≤δ≤0.17 mm), with minimum breakdown voltage values specified for room temperature and high temperature conditions.

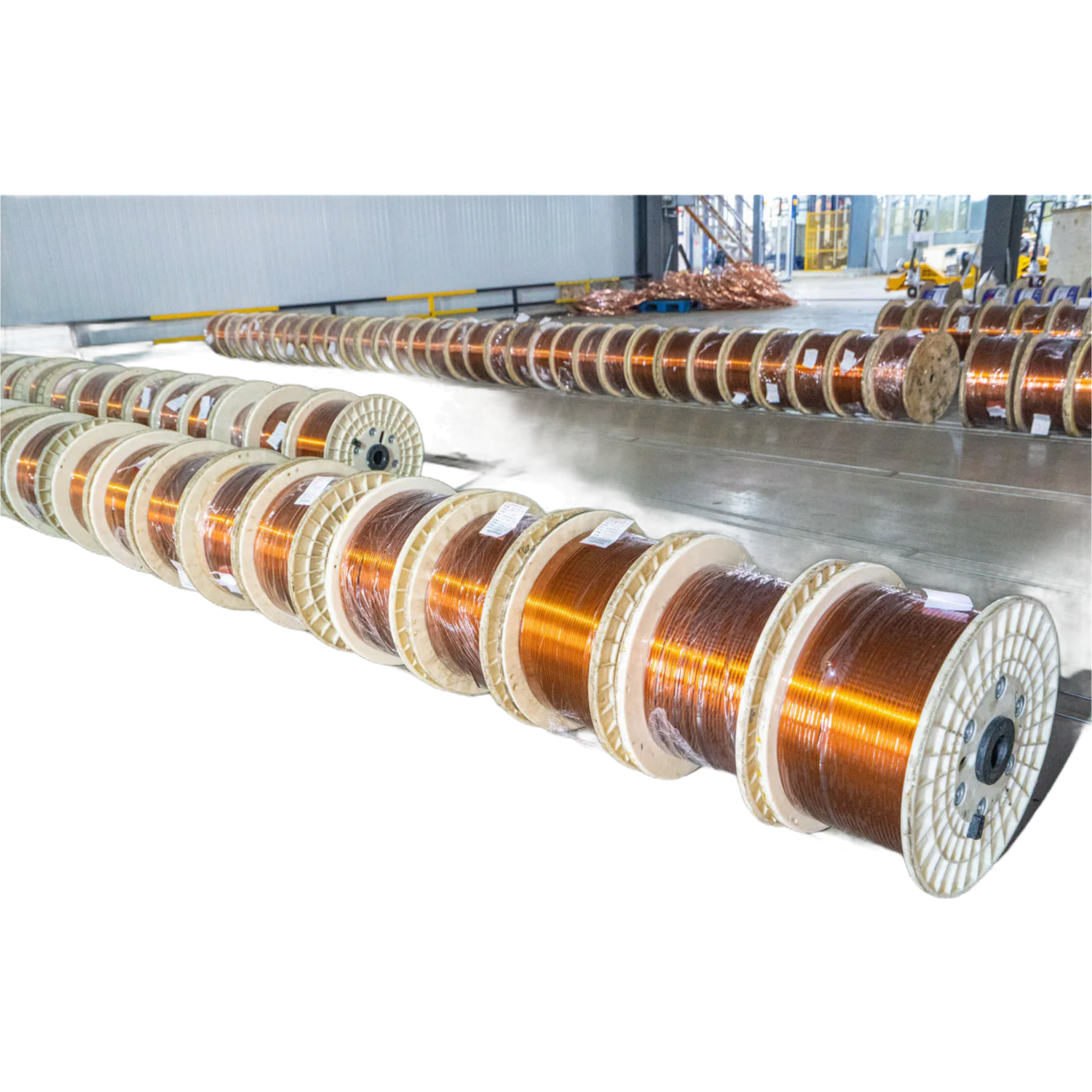

Beyond expectations in every aspect of the transaction. Beginning with logistics, the delivery was remarkably prompt and well-organized. The shipment arrived ahead of schedule, securely packaged with clear labeling, which made the receiving process straightforward and efficient. There were no delays or complications, reflecting a highly professional logistical operation. Regarding quality, the flat wire received is exceptional. The materials feel robust and precisely manufactured, with a consistent enamel coating that appears flawless. It aligns perfectly with the specifications discussed, and the craftsmanship suggests meticulous attention to detail, reinforcing confidence in the product’s reliability for industrial applications. As for service, the supplier’s team was outstanding. From initial inquiries to post-delivery follow-up, communication was clear, responsive, and courteous. They provided thorough updates and were readily available to address any questions, ensuring a smooth and reassuring experience. Overall, this supplier demonstrates a commendable commitment to excellence, making them a highly recommended partner for anyone seeking quality electrical components.

The transaction was thoroughly positive. Timely delivery was a standout feature, with the shipment arriving precisely as scheduled without any delays. Tracking information was consistently updated and accurate, allowing for seamless logistics planning. The packaging was exceptionally secure, ensuring the products arrived in flawless condition without any signs of damage or mishandling during transit. This attention to protective detail reflects a high standard of operational care. Regarding the materials received, the quality appears impeccable. The enameled flat wire exhibits a uniform coating and consistent dimensions, aligning perfectly with the specifications outlined in our order. The physical integrity and finish suggest rigorous manufacturing controls, which is reassuring for our application in transformer windings. Communication from the supplier was transparent and professional throughout the entire process. Queries were addressed promptly and with clear, helpful information. The overall service experience was efficient and courteous, fostering confidence in a potential ongoing partnership. This supplier demonstrates a commendable commitment to reliability and customer satisfaction across logistics, product integrity, and support.

Xcellent experience from start to finish. The logistics were handled flawlessly; the shipment arrived ahead of schedule and was packaged with exceptional care, ensuring the enameled flat wire was in perfect condition upon arrival. The quality of the materials is immediately apparent, meeting the high standards one would expect from an ISO9001 certified supplier. The flat wire for our transformer windings exhibits superior consistency in the enamel insulation, which is critical for our applications. Regarding service, the communication was proactive, clear, and highly professional. The team was responsive to our initial inquiry about custom specifications and provided thorough support throughout the ordering process. They demonstrated a deep understanding of technical requirements for electrical aluminum and copper wire, offering valuable insights. This supplier has proven to be reliable and knowledgeable, making the procurement process seamless and efficient. I am thoroughly impressed and would not hesitate to recommend them or place future orders for our insulation paint and other wire needs.

Logistics were handled exceptionally well. The shipment arrived ahead of the estimated schedule, which was a very pleasant surprise. The packaging was robust and secure, ensuring the product arrived in pristine condition without any damage. The tracking information provided was accurate and updated regularly, allowing for complete peace of mind throughout the transit process. The carrier used was professional, and the delivery was seamless. Overall, the logistical execution was flawless and highly commendable. Regarding quality, the product itself meets the highest standards. The materials used are evidently premium, and the craftsmanship is precise. It is clear that great care and attention to detail went into the manufacturing process. The product specifications appear to have been followed meticulously, resulting in a reliable and durable item. The finish is excellent, and it performs exactly as one would expect from a supplier with such certifications. The quality assurance is noticeable and very reassuring. In terms of service, the experience was outstanding from start to finish. The customer service team was responsive, knowledgeable, and genuinely helpful. All inquiries were addressed promptly and with clear, thorough information. The ordering process was straightforward, and any preliminary questions were answered with patience and expertise. The after-sales support has also been attentive, demonstrating a commitment to customer satisfaction that goes beyond the initial transaction. The service provided was professional, courteous, and efficient, making the entire process a pleasure.

Rapid delivery and excellent packaging. The order arrived ahead of schedule, which was a pleasant surprise. The flat wire was securely packaged, preventing any damage during transit. The quality of the enameled flat wire appears to be very high, with a consistent coating and no visible imperfections. Customer service was responsive and helpful when I had a question about the order. Overall, a very satisfactory experience with this supplier.

Delivery was exceptionally prompt and well-handled. The packaging was secure and professional, ensuring the products arrived in perfect condition without any delays. The quality of the enameled flat wire is outstanding, meeting all specified requirements with precision. Customer service was responsive and helpful throughout the entire process, providing clear communication and support. Overall, a very satisfactory experience from start to finish.

Rapid and reliable delivery was the first thing that impressed me. The logistics were handled flawlessly, with clear communication at every stage. Regarding the quality, the flat wire arrived in perfect condition, securely packaged, and the materials themselves appear to be of excellent grade. The service team was exceptionally responsive and professional, answering all my preliminary queries promptly and accurately. The entire process from inquiry to receipt was smooth and instilled great confidence. This supplier clearly understands the importance of customer support and operational efficiency. A very positive experience overall, highly recommended for anyone needing dependable materials and service.

Absolutely fantastic experience from start to finish. The delivery was incredibly prompt and the packaging was secure, ensuring the product arrived in perfect condition. Regarding the quality, the enameled flat wire appears to be manufactured to a very high standard; the insulation looks uniform and robust. The customer service team was exceptionally responsive and helpful throughout the ordering process, answering all my preliminary questions clearly and efficiently. They provided excellent support, which made the entire transaction smooth and worry-free. I am thoroughly impressed with the overall service and the apparent quality of the materials received. This supplier clearly prioritizes customer satisfaction and reliable logistics. A highly commendable service all around.

WOW! The entire experience with this supplier was absolutely phenomenal, and it truly exceeded my expectations in every possible way. Starting with the logistics, the shipping was incredibly fast and efficient. The order was processed promptly, and I received clear tracking information almost immediately. The flat wire arrived well ahead of the estimated delivery date, which was a fantastic surprise and helped us keep our production schedule on track. The packaging was exceptionally secure and professional, ensuring that the delicate enameled wire was perfectly protected during transit. There was no damage whatsoever, which is crucial for such precision materials. Regarding quality, the product itself is outstanding. The enameled flat wire appears to be manufactured to the highest standards. The insulation coating is uniform and smooth, with no visible imperfections or inconsistencies. It meets our exacting specifications perfectly, and the material quality of the underlying copper conductor seems excellent. While I cannot comment on long-term performance yet, the initial electrical tests we have conducted show superb results, exactly as specified. The service provided by the company was equally impressive. From the initial inquiry through to the final delivery, communication was clear, responsive, and highly professional. The sales team was knowledgeable and patient, answering all our technical questions about thermal classes and custom specifications thoroughly. They provided detailed documentation and certificates without delay, which streamlined our internal quality assurance process. The overall professionalism and commitment to customer satisfaction are evident. This was a seamless, reliable, and high-quality procurement experience from an ISO-certified supplier I would not hesitate to recommend to others or use again for future projects requiring precision electrical components.

Keenly satisfied with the entire procurement process for the enameled flat wire. The logistics were handled exceptionally well; the shipment arrived ahead of the estimated schedule, which was a pleasant surprise and greatly assisted our project timeline. The packaging was robust and secure, ensuring the materials were in perfect condition upon arrival. Regarding quality, the flat wire appears to be manufactured to a very high standard, consistent with the supplier’s ISO9001 certification. The finish and insulation seem impeccable, exactly as specified for our transformer windings. The service provided was outstanding from start to finish. The sales team was responsive, knowledgeable, and proactive in communication, making the custom specification process smooth and straightforward. They provided clear documentation and were very professional throughout. Overall, this was a highly positive experience, and the supplier has proven to be reliable and competent. I would not hesitate to recommend them to others in need of quality electrical winding materials and would certainly consider them for future orders.