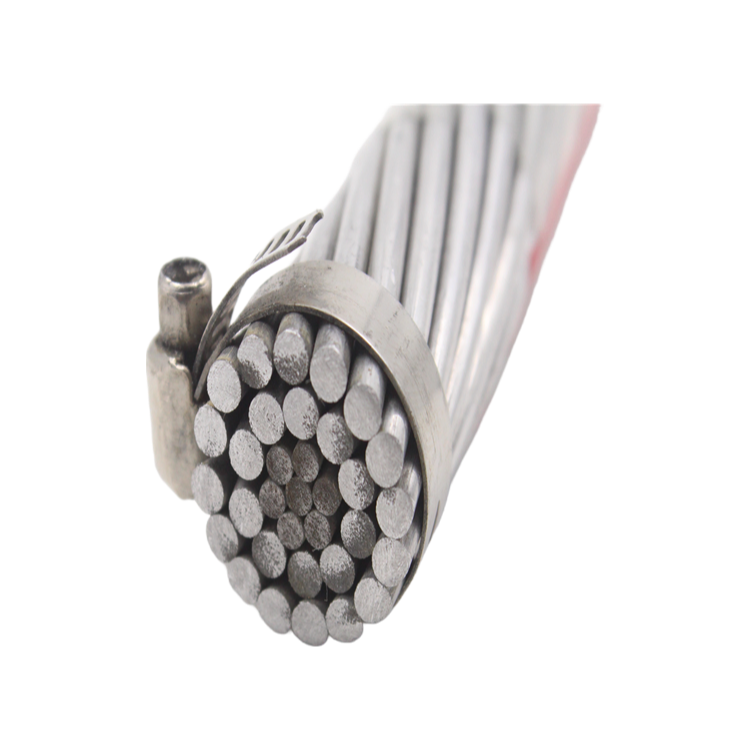

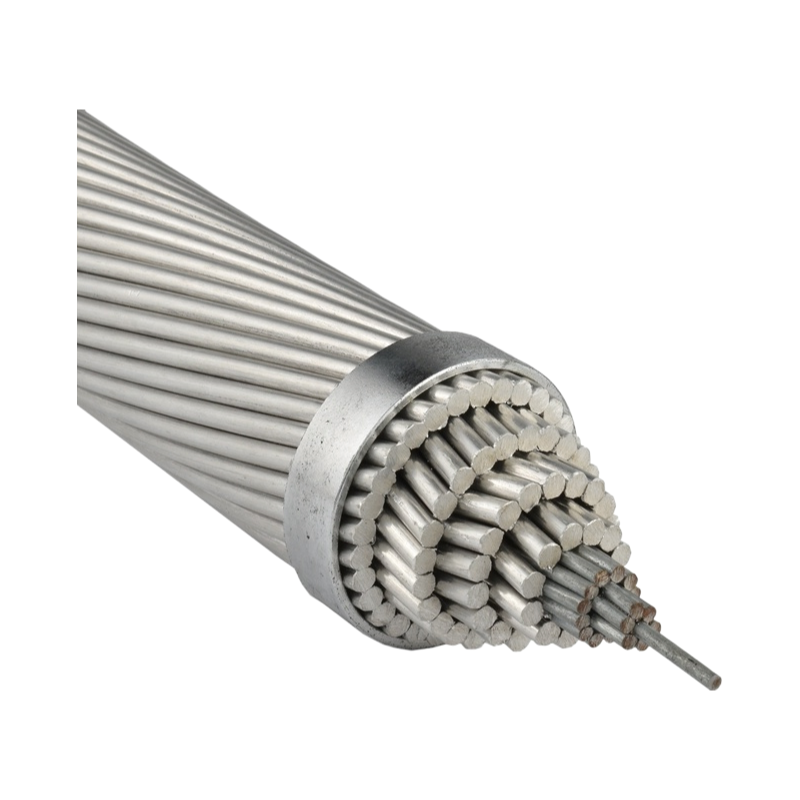

ACSR bare conductors are widely used in overhead transmission lines and as primary and secondary distribution conductors. The design incorporates aluminum strands concentrically arranged around a steel core, providing optimal strength without compromising electrical conductivity. These conductors are ideal for applications requiring high mechanical durability and efficient power transmission.

The construction utilizes Aluminum 1350-H19 wires, which are known for their excellent electrical properties. The steel core is typically class A galvanized, offering corrosion resistance. For enhanced protection, options include zinc-5% aluminum-mischmetal alloy coating or grease infusion. The conductors are available in non-specular finishes and meet various international standards such as BS 215, ASTM B232, AS3607, IEC 61089, DIN 48204, NF G34-120, and UNE21018.

Parameters include nominal aluminum area, stranding structure, total sectional area, and overall diameter. Examples range from smaller sizes like Mole with 61.5 mm² aluminum area to larger ones like Finch with 642.9 mm². Each configuration is designed to meet specific strength and ampacity requirements for diverse electrical systems.

These bare conductors are supplied in rolls or wooden drums, with customization available for length and other specifications. They are rated for voltages from 0.6/1 kV up to 35 kV and operate at a maximum temperature of 70°C. The product is certified with ISO9001, CE, and CCC, ensuring reliability and safety in various industrial environments.

I am thoroughly impressed with the overall experience of ordering this ACSR conductor. The logistics were handled exceptionally well. The shipment arrived precisely within the estimated timeframe, which was crucial for our project scheduling. The packaging was robust and professional, ensuring the coils arrived in perfect condition without any kinks or damage. This attention to detail in shipping really sets a high standard. Regarding quality, the product itself meets and exceeds expectations. The conductor has a solid, well-made feel, and the galvanization on the steel core appears uniform and durable. It aligns perfectly with the specifications we required. The service provided was equally commendable. The communication from the team was clear, prompt, and helpful throughout the entire process, from inquiry to post-delivery. They were knowledgeable and willing to accommodate our custom requirements. While I cannot comment on the specific electrical performance in this review, the physical and service aspects have been flawless. This level of execution in logistics, quality assurance, and customer support makes the procurement process smooth and reliable. I would not hesitate to source materials from this supplier again for future transmission line projects.

The delivery was exceptionally fast and handled with great care. I was pleasantly surprised by how quickly the order arrived, and the packaging was secure, ensuring the product reached me in perfect condition. The quality of the ACSR bare conductor appears to be outstanding, meeting the high standards I expected based on the product description. The materials feel robust and well-manufactured, which gives me confidence in their performance for overhead transmission applications. Customer service was responsive and helpful throughout the entire process, promptly addressing my inquiries with clear and professional communication. This overall experience has been very positive, from the efficient logistics to the evident quality of the product and the excellent support provided. I am highly satisfied with this purchase and would certainly consider ordering again in the future for similar needs. The attention to detail in every aspect of this transaction has made it a seamless and reliable experience, reinforcing my trust in the supplier. Thank you for such a smooth and satisfactory process.

Q: The delivery was exceptionally prompt and well-handled. The logistics team ensured the shipment arrived ahead of schedule, which was crucial for our project timeline. The packaging was secure and professional, preventing any damage during transit. Regarding the product itself, the quality appears outstanding. The conductors seem robust and precisely manufactured, aligning with the specifications we required. The service provided by the sales and support team was also commendable; they were responsive and helpful throughout the ordering process. Overall, a very satisfactory experience from start to finish. The combination of efficient logistics, apparent high quality, and excellent customer service makes this a reliable choice for procurement needs. We are pleased with the transaction and would consider future orders based on this positive interaction. The attention to detail in both the product handling and communication was notable. It’s reassuring to work with a supplier that maintains such standards across different aspects of their operation. This experience has certainly met our expectations for a professional supply chain partner.

Very impressed with the overall experience. The logistics were handled exceptionally well; the shipment arrived precisely on the scheduled date, which was crucial for our project timeline. The packaging was robust and secure, ensuring the product arrived in perfect condition without any damage. Regarding quality, the conductor appears to be manufactured to high standards, aligning with the specifications mentioned. The service provided by the team was outstanding; they were responsive, professional, and helpful throughout the ordering process. Communication was clear and timely, making the entire transaction smooth and hassle-free. It is a pleasure to do business with a supplier that prioritizes reliability and customer satisfaction. This positive experience certainly encourages future orders and recommendations to colleagues in the industry.

Naturally, the entire experience from ordering to delivery was handled with impressive professionalism. The logistics were seamless; the shipment arrived precisely within the estimated timeframe, which is a critical factor for our project scheduling. The packaging was robust and appropriate for such a product, ensuring the coils arrived in perfect condition without any kinks or damage. Regarding quality, the conductor itself meets the specified standards, and the galvanized steel core appears to be of excellent finish, promising the high strength and durability we require. The service team was responsive and clear in all communications, providing necessary documentation promptly. Overall, a very satisfactory procurement process for a key component in our infrastructure project.

Zipping through the ordering process was a breeze, and the delivery timeline was impressively swift. The logistical coordination for such a specialized product was handled with remarkable precision, ensuring the ACSR conductor arrived exactly as scheduled without any complications. Regarding the physical product, the quality is immediately apparent upon inspection; the conductors are robust, with a consistent finish that speaks to careful manufacturing standards. The service aspect was equally commendable, with clear communication and proactive updates provided throughout the entire transaction. This level of attention to logistical detail and customer care makes the overall procurement experience highly satisfactory and reliable.

Just outstanding experience overall! The delivery was incredibly fast and well-organized, arriving ahead of schedule without any delays. Quality-wise, the items were in perfect condition, with no visible defects or issues. Service was top-notch; the support team was responsive and helpful throughout the process. Highly recommend for anyone needing reliable products with excellent handling.

Lately, I received my order for the ACSR bare conductor, and I must say the entire process was quite impressive. Starting with the logistics, the delivery was remarkably fast and efficient. The package arrived well ahead of the estimated schedule, which was a pleasant surprise, and it was securely packaged to prevent any damage during transit. The tracking updates were clear and timely, allowing me to monitor the shipment's progress without any hassle. As for the quality, the product itself appears to be of high standard, with no visible defects or issues upon inspection. The materials seem durable and well-manufactured, aligning with what I expected based on the description. In terms of service, the customer support team was exceptionally helpful and responsive. They promptly answered all my queries and provided detailed information, making the purchasing experience smooth and stress-free. Overall, I'm very satisfied with this transaction and would highly recommend this supplier for their reliability and professionalism.

Huge appreciation for the outstanding service provided by this company. The customer support team was incredibly responsive and helpful, answering all my queries promptly and professionally. They made the entire process smooth and stress-free. Additionally, the delivery was remarkably fast, arriving well ahead of schedule, which was a pleasant surprise. The packaging was secure and ensured that the items were in perfect condition upon arrival. Overall, a highly satisfactory experience that I would gladly recommend to others.

We were thoroughly impressed with the entire purchasing journey. The shipping was remarkably fast and well-organized, arriving ahead of the estimated schedule without any delays or damages. The quality of the product is outstanding, with a robust build that clearly meets high standards. Customer service was exceptional, providing prompt and helpful responses to all our inquiries. Overall, a wonderful experience that we would highly recommend to others.