Our factory specializes in manufacturing high-quality custom jigsaw puzzles for various applications including gifts, promotions, education and entertainment. We offer flexible customization options to meet different market demands.

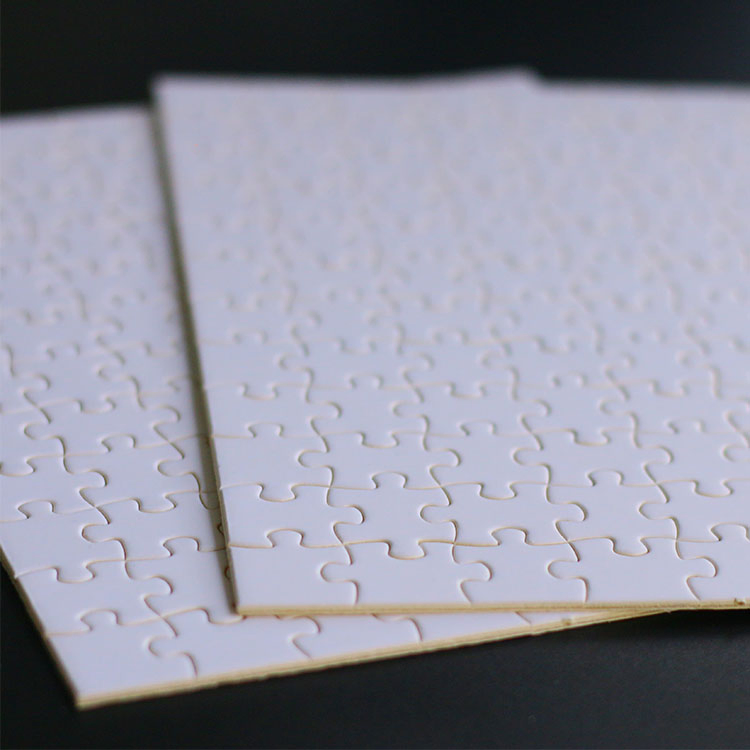

Material Options: We produce puzzles using three main materials - paper (grey/white/blue/black card), wood, and environmentally friendly degradable plastic. Each material offers unique characteristics for different puzzle experiences.

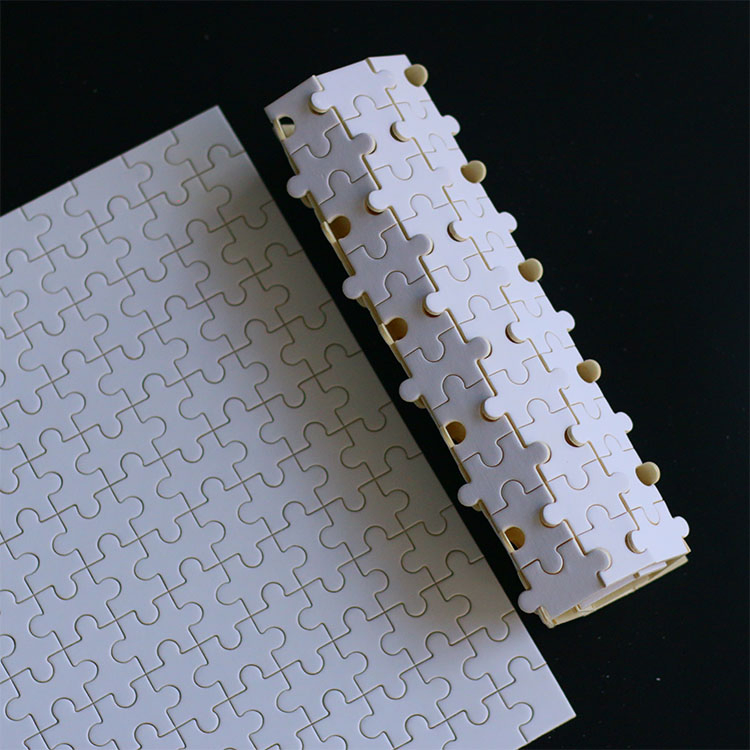

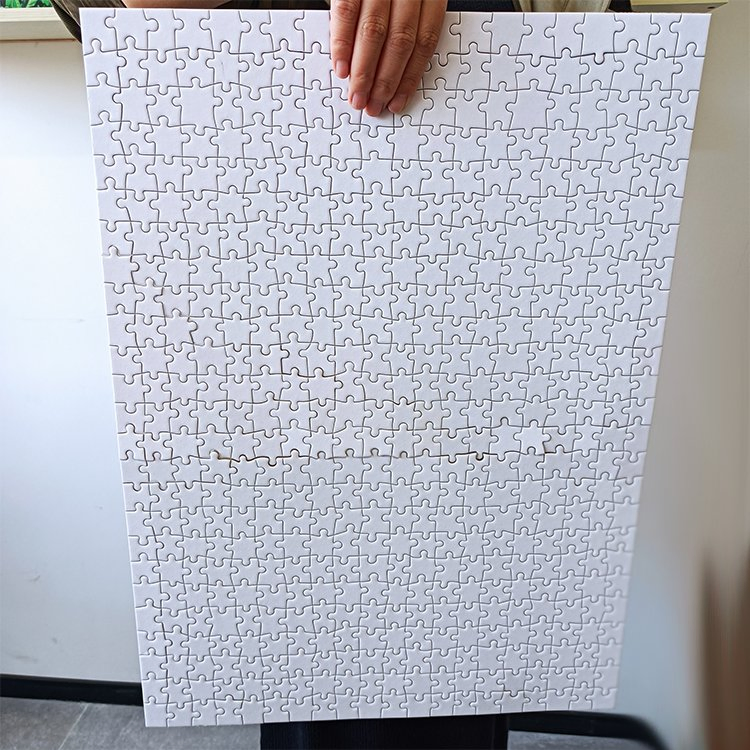

Size & Thickness: Available in standard sizes from our existing molds or customized dimensions. Common thickness options include 1.8mm, 2mm, 2.3mm, 2.5mm and 3mm, with flexibility to adjust based on product requirements.

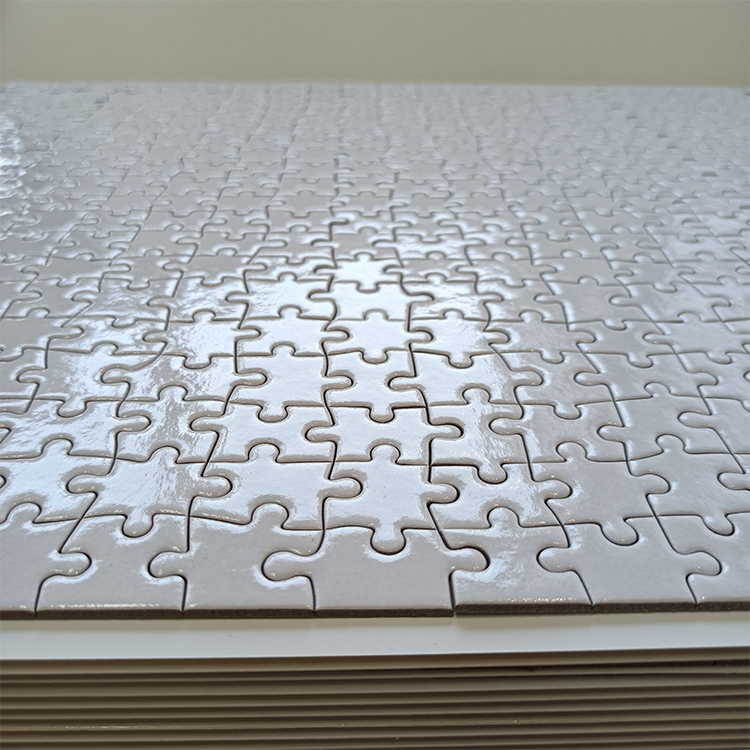

Printing & Finishing: Professional CMYK and PMS color printing options. Surface finishes include varnish, lamination, linen texture, and special treatments like UV coating or gold stamping for premium effects.

Puzzle Shapes: Standard rectangular, round, square and heart shapes available, plus capability to create custom special shapes based on client designs.

Packaging Solutions: Standard top-bottom boxes or customized options including magnetic boxes, tuck boxes and tubes. Packaging can feature various finishes matching the puzzle design.

For challenging puzzles, we can produce pieces with random die-cut patterns and plain backs. For easier assembly, we offer reference posters or zoning letters on piece backs. Our technical team can advise on optimal piece thickness and locking mechanisms.

Production Capacity: With over 100 existing die-cut molds, we can quickly produce samples (3 days for free samples, 1 week for custom samples) and complete mass production within 3-4 weeks.

Crafting a custom puzzle was a seamless experience from start to finish. The logistics were handled with remarkable efficiency; the order was processed promptly and the shipping was both swift and reliable, with the package arriving well-protected and ahead of schedule. The quality of the final product is truly outstanding. The printing is vibrant and precise, with sharp details and excellent color fidelity using the CMYK options we selected. The puzzle pieces themselves are sturdy, cut cleanly to our specified custom shape, and have a satisfying feel. The service provided by the team was exceptional. Communication was clear, professional, and responsive throughout the entire OEM process, from initial inquiry to final confirmation. They were attentive to our specifications and provided helpful guidance. This manufacturer demonstrates a clear commitment to quality and customer satisfaction, making them a superb partner for custom projects.

Communication with this OEM puzzle factory was consistently clear and professional from the initial inquiry. They provided comprehensive details about their custom shape, size, and printing options, which was incredibly helpful. The quality of the final product is outstanding. The pieces of our custom wooden puzzle fit together perfectly with a satisfying snap, and the CMYK printing on our complex design is vibrant and crisp, with no blurring or pixelation. The packaging was secure and arrived without any damage. The service team was responsive and patient, guiding us through the PMS color matching process to ensure our brand colors were perfectly replicated. For anyone looking for a reliable manufacturer for wholesale educational toys or custom plastic puzzles, this factory demonstrates expertise and a strong commitment to customer satisfaction. The entire process, from design approval to final delivery, was handled efficiently.

Rapid and reliable delivery was the first thing that impressed me. The logistics were handled flawlessly from start to finish, with clear tracking updates and the package arriving ahead of schedule in perfect condition. This efficiency set a very positive tone for the entire experience. Regarding the product quality, it is truly outstanding. The materials feel premium and durable, with excellent finishing and precise manufacturing. Every aspect from the packaging to the final product exudes a sense of high standards and careful attention to detail. The service provided was equally commendable. The support team was responsive, professional, and genuinely helpful throughout the process, answering all inquiries promptly and accurately. Communication was clear and courteous, making the transaction smooth and worry-free. Overall, this was a seamless experience from ordering to receipt, marked by superior logistics, exceptional quality, and exemplary customer service. I am thoroughly satisfied and would not hesitate to recommend them based on these core strengths.