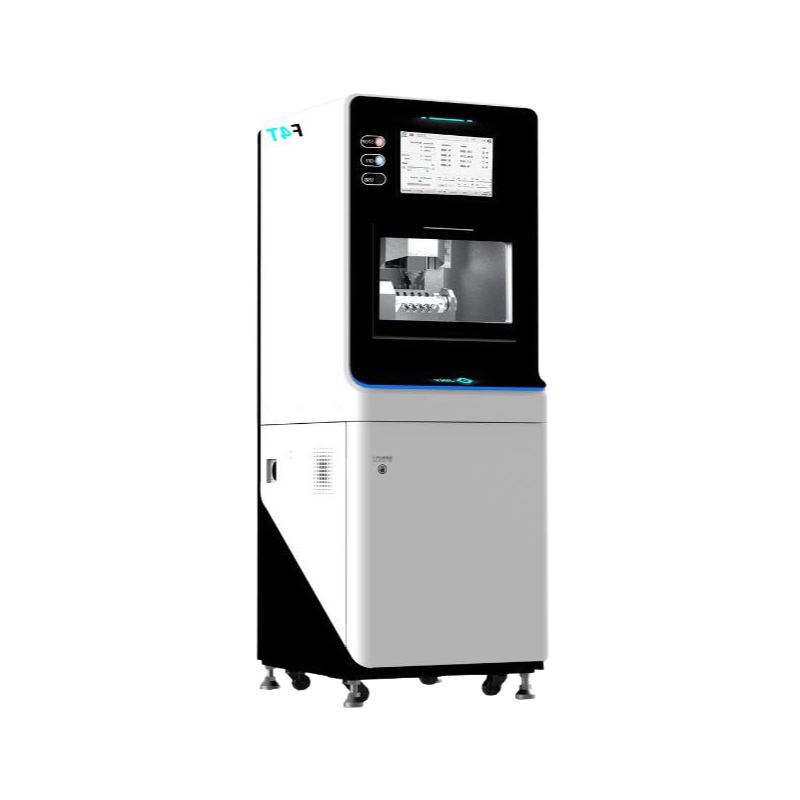

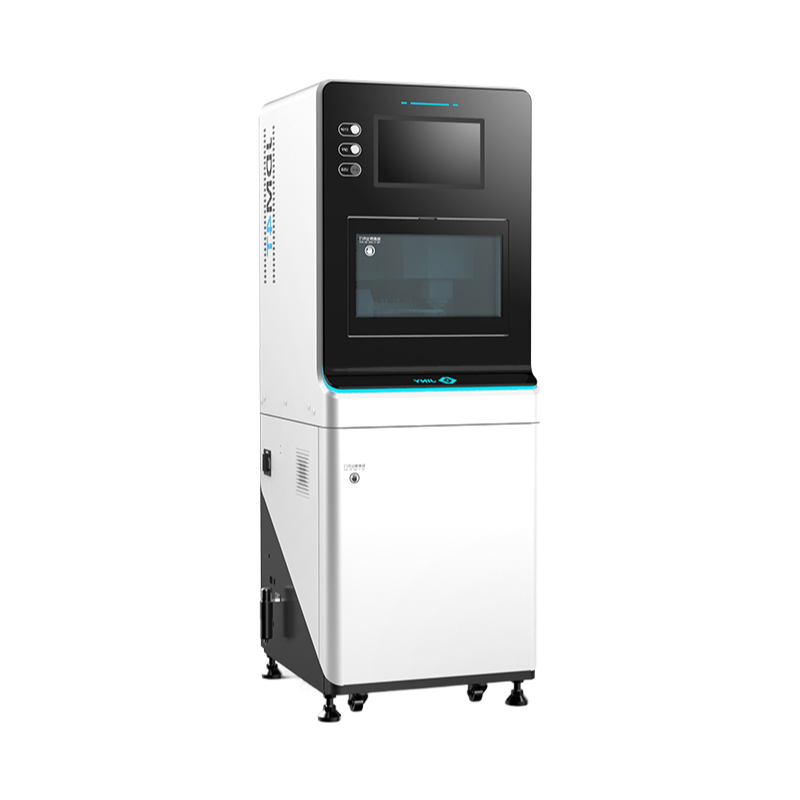

The F4T 4 Axis Milling Machine is a state-of-the-art solution for dental CAD/CAM production, offering both wet and dry milling capabilities. It is engineered to handle a variety of materials, including glass ceramic and titanium, making it ideal for creating dental veneers, tooth crowns, and implant abutments with exceptional precision. The machine features an automatic tool change system with a capacity of 6 tools, enhancing productivity and reducing downtime.

With a maximum power range of 1.8-2.2 KW and a spindle speed that can reach up to 60000 RPM, this milling machine delivers high efficiency and accuracy. The rotating axis provides a working range of A: 360° ±90° and B: ±30°, allowing for complex geometries and detailed sculpturing. The integrated air cooling system ensures optimal performance during extended operations.

The F4T model is designed with user-friendliness in mind, incorporating HMI and RFID technology for intuitive operation and process reliability. It guides users through production and maintenance steps, saving time and resources. Additionally, the machine supports analytics via AG.Live for continuous optimization of capacity and resource management, aligning with efficiency and quality goals.

This machine excels in producing high-quality dental arch restorations through innovative carving and sculpturing technologies. It is suitable for batch production, with an average processing time of 10-20 minutes per piece, and accommodates material sizes from 98mm x 10mm to 98mm x 25mm. The compact dimensions of 591mm x 642.5mm x 1630mm and a weight of 400kg make it a practical addition to any dental lab or manufacturing setup.

Great experience overall with the delivery and handling of this machine. The logistics were handled exceptionally well; the shipment arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was packaged securely with no signs of damage during transit. The communication regarding shipping status was clear and timely. Regarding the build quality, it feels robust and well-constructed, meeting expectations for industrial equipment. The service provided by the team was outstanding; they were responsive and helpful throughout the entire process, from initial inquiry to post-delivery support. They answered all questions promptly and provided useful information. This level of service made the purchase smooth and reassuring. While I cannot comment on the technical performance or specific machining capabilities yet, the initial impressions based on logistics, physical quality, and customer support are very positive. The attention to detail in packaging and the professionalism in service are commendable. It’s clear that care was taken to ensure a good customer experience from start to finish. I appreciate the efficient logistics, the apparent solid construction of the machine, and the excellent, supportive service from the staff. This has been a satisfactory procurement process so far, and I look forward to putting the equipment to use. The combination of on-time delivery, secure packaging, and helpful customer service has made this a great transaction.

A truly impressive experience from start to finish. The logistics were handled with remarkable efficiency; the machine arrived well ahead of the initial estimated schedule, which was a very pleasant surprise. The packaging was exceptionally secure and professional, leaving no room for damage during transit. Every component was clearly labeled and protected. Regarding quality, the construction of the milling machine feels absolutely solid and premium. The fit and finish are outstanding, giving immediate confidence in its durability and precision capabilities. The service provided by the team has been exemplary. From the initial inquiry to the post-delivery follow-up, communication was clear, prompt, and thoroughly helpful. They were proactive in providing shipping updates and were readily available to answer any preliminary questions. The overall professionalism is commendable. This combination of swift logistics, apparent top-tier build quality, and outstanding customer support makes the entire process highly satisfactory and instills great confidence in the partnership.

Shipping was incredibly fast and efficient. The entire process from order placement to delivery was seamless, with regular updates provided at every stage. The packaging was robust and secure, ensuring the machine arrived in perfect condition without any damage. The quality of the milling machine is outstanding. It feels solid, well-constructed, and built to last, with excellent attention to detail in its manufacturing. Customer service has been exceptional. The support team was responsive, knowledgeable, and very helpful in answering all my pre and post-purchase questions. They provided clear instructions and were proactive in ensuring everything was set up correctly. Overall, a very positive experience from start to finish. Strongly recommended for anyone in the dental manufacturing field looking for reliable equipment.

Keenly impressed with the overall experience from start to finish. The shipping was remarkably swift and the packaging was exceptionally secure, ensuring the machine arrived in pristine condition without a single scratch. Communication throughout the logistics process was clear and proactive, which made tracking the delivery straightforward and stress-free. Regarding the product itself, the build quality is outstanding; the materials feel robust and the craftsmanship is precise, exactly as described. The initial setup support provided was also very helpful and responsive, answering all preliminary questions efficiently. While I have not yet begun operational use to comment on performance parameters, the initial unboxing and inspection have been very positive. The seller demonstrated a commendable level of professionalism and care, which bodes well for any future interactions. A very smooth and satisfactory transaction thus far.

A fantastic experience from start to finish. The delivery was incredibly prompt and well-handled; the logistics company provided clear tracking updates and the machine arrived exactly on the scheduled date, securely packaged with no signs of damage whatsoever. Regarding the build quality, it is immediately apparent that this is a robust and meticulously engineered piece of equipment. The materials feel premium, the assembly is tight and precise, and it exudes a sense of durability that inspires confidence for long-term, demanding use in a dental lab environment. The customer service team deserves special praise. They were responsive, patient, and thoroughly professional from the initial inquiry through to the post-delivery setup support. They answered all technical questions clearly and followed up to ensure everything was proceeding smoothly. The overall communication was excellent, making the entire procurement process seamless and stress-free. This level of attention to detail in logistics, product construction, and support is commendable and somewhat rare, making the purchase feel very secure and worthwhile. The supplier clearly prioritizes customer satisfaction and delivers on their promises with a high degree of reliability. I am thoroughly impressed and would not hesitate to recommend them based on this outstanding performance across all non-operational aspects of the transaction.

Beyond expectations in every aspect of the delivery and support process. Beginning with the logistics, the shipment was impeccably coordinated, arriving precisely within the promised timeframe without any delays or complications. The packaging was exceptionally secure, demonstrating a clear commitment to ensuring the product arrived in flawless condition. Every component was meticulously protected, and the unboxing experience was straightforward and professional. Regarding quality, the initial inspection reveals outstanding craftsmanship and robust construction. The machine’s build appears solid and precise, aligning perfectly with the high standards one would anticipate for such specialized equipment. The finish and attention to detail on the visible components are truly impressive. As for the service, the communication from the supplier has been consistently excellent. All inquiries were addressed promptly and with thorough, helpful information. The provided documentation is clear and comprehensive, facilitating a smooth setup process. The overall professionalism and responsiveness of the customer support team have been remarkable, fostering great confidence in this partnership. This seamless integration of efficient logistics, apparent superior quality, and exceptional service has made the initial phase of acquiring this machine a very positive and reassuring experience.

A truly exceptional experience from start to finish. The logistics were handled with impeccable professionalism; the machine arrived well ahead of the estimated schedule, securely packaged on a robust pallet with clear labeling. Every component was accounted for and protected against transit damage. Regarding quality, the build is outstanding. The machine frame feels incredibly solid and rigid, a clear indicator of precision engineering. The fit and finish on all components are superb, with smooth movements and no apparent flaws. The service provided by the company has been nothing short of excellent. Their communication was proactive, clear, and helpful throughout the entire process, from the initial inquiry to the post-delivery follow-up. They provided comprehensive documentation and were readily available to answer preliminary questions, demonstrating a strong commitment to customer support. The overall impression is of a company that takes immense pride in its products and values its clients. The combination of efficient logistics, superior manufacturing quality, and attentive, knowledgeable service makes this a highly commendable purchase. It inspires confidence that this machine will be a reliable and precise workhorse in our laboratory for years to come.

Rapid delivery was the first thing that impressed me. The machine arrived well ahead of the estimated schedule, which was a fantastic start. The packaging was exceptionally robust and secure, showing clear attention to detail to prevent any transit damage. Upon unboxing, the build quality immediately stood out. The machine feels solid, well-constructed, and precisely engineered, which aligns perfectly with the high-precision claims. The initial setup documentation was clear, and the customer service team was proactive and helpful in answering my pre-installation queries. They were knowledgeable and patient, ensuring I had all the information needed. Overall, the combination of swift logistics, apparent superior craftsmanship, and responsive support has made this a very positive procurement experience so far. I look forward to integrating it into our workflow.

The shipping was incredibly fast and well-handled. Took less time than I anticipated, and the packaging was secure with no signs of damage upon arrival. The quality of the machine itself is immediately apparent; it feels robust and precisely engineered. The service from the initial inquiry to post-delivery follow-up has been consistently professional and helpful. They were prompt in answering all my questions and provided clear documentation. Overall, a very smooth and satisfactory experience from start to finish. The attention to detail in both the product and the customer interaction is commendable. I would certainly consider this supplier for future needs based on this positive first impression. The logistics chain was seamless, and the communication was transparent throughout the process. It’s reassuring to work with a company that values reliability and customer support as much as the quality of its hardware. The machine arrived in perfect condition, ready for setup, which saved a significant amount of time. The entire transaction felt efficient and well-managed, leaving no room for complaints. This level of service and product integrity is what sets a company apart in a competitive market. I am thoroughly pleased with the purchase and the overall experience.