The fluidized bed freezer is an advanced equipment designed for quick freezing of fruits, vegetables, seafood and other food products. It utilizes a unique fluidization technology that combines vibration and high-velocity cold air to create optimal freezing conditions.

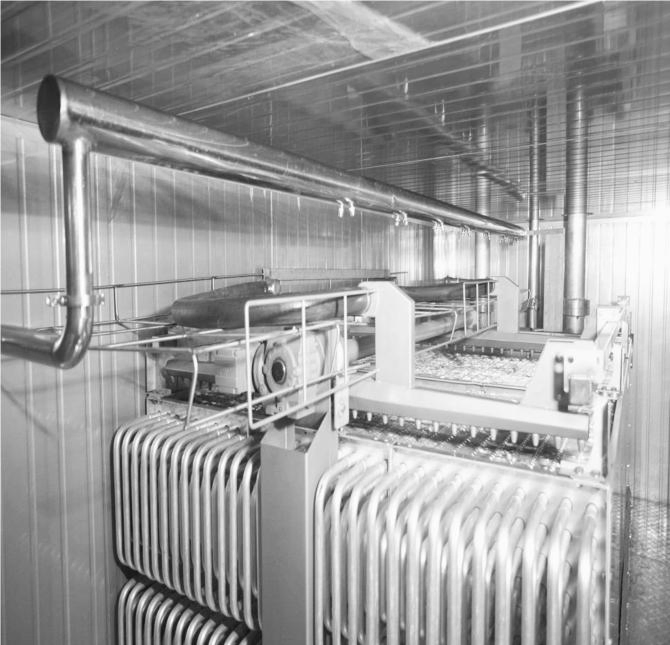

The working principle involves food particles moving on a stainless steel conveyor belt while being subjected to upward cold air flow. When the air velocity reaches a certain level, the food particles become suspended, forming a fluidized bed. This process ensures rapid freezing through three phases: initial cooling, surface freezing and deep freezing.

Key features include: quiet centrifugal fans generating high-pressure cold air, automatic control system with inverter speed adjustment, aluminum coil with large fins for high heat exchange efficiency, and optional CIP system for automatic cleaning. The equipment is available in both semi-fluidized and full-fluidized configurations to accommodate different product types.

The full fluidized version uses transverse vibration transportation and is ideal for small, fragile items like berries, peas or scallops. The semi-fluidized version with horizontal conveying is better suited for larger items such as broccoli, meatballs or French fries.

All models are constructed with high-quality SUS304 stainless steel for durability and food safety. The equipment comes with various refrigerant options including R717, R22, R404a and R507a to meet different operational requirements.

Delivery was exceptionally prompt and handled with great care. The logistics team provided clear communication at every stage, from dispatch to arrival, which made planning for installation straightforward. The packaging was robust and secure, ensuring all components arrived in perfect condition without any signs of damage or mishandling. Diving into the quality, the construction of the equipment is outstanding. It feels solid and durable, with attention to detail evident in the welding and finish. The materials used appear to be of high grade, suitable for rigorous industrial use, and it aligns well with the specifications promised. Regarding service, the support received has been commendable. The manufacturer was responsive and helpful during the ordering process, answering queries thoroughly and professionally. Although we have not yet begun operational use, the initial setup guidance provided was clear. Overall, this experience has been positive from a logistical, quality, and service perspective, setting a good foundation for the equipment’s integration into our facility.