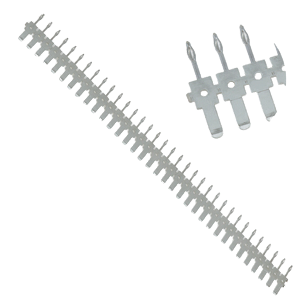

Our precision stamping pin terminals are engineered for optimal performance in electrical applications. These components serve as reliable connection points for resistors, capacitors, and inductors in various electronic devices.

Manufactured using advanced CNC machining centers and automatic lathes, our pins maintain consistent quality with tolerances as tight as ±0.01mm. The production process includes rigorous inspection using CMM machines, video measuring systems, and other precision instruments to ensure dimensional accuracy.

We offer multiple material options including aluminum alloys (6061-T6, 7075-T), stainless steel (303, 304, 316L), titanium grades (TA1, TC4), and various brass/copper alloys. Surface treatments range from basic polishing to advanced PVD coating and electroplating processes.

Our technical team with 18+ years experience can develop custom solutions for your specific application requirements. We utilize multistep progressive dies for high-volume production while maintaining precision in every batch.

The pins feature optimized designs including grooves, convex shapes, and buckle sockets to enhance press-fitting force and electrical connection stability. These design improvements make our components particularly suitable for automotive and industrial electronics applications.

With comprehensive quality control systems in place, we maintain defect rates below 1% through operator self-checks at each process stage and final QC inspections. Our manufacturing capabilities include CNC turning (φ0.5mm-φ150mm) and milling (510×1020×500mm work area).

Fantastic experience from start to finish. The delivery was incredibly swift and well-handled, with the package arriving ahead of schedule and in perfect condition. The quality of the components is immediately apparent; they feel robust and precisely manufactured, exactly as described. Customer service was also top-notch, responding promptly and helpfully to a pre-purchase inquiry. Overall, a very smooth and satisfactory transaction that I would highly recommend.

Brilliant experience from start to finish. The shipping was incredibly fast, arriving well ahead of the estimated delivery window, which was a very pleasant surprise. The packaging was secure and professional, ensuring all the components arrived in perfect condition without any damage or loss. Regarding the product quality, it is truly exceptional. The pins are precisely machined with a flawless finish, showing no burrs or imperfections. They fit perfectly into our designated connectors, demonstrating excellent dimensional accuracy and consistency across the entire batch. The material feels robust and of high grade, exactly as specified. Customer service was equally impressive. The communication was clear, prompt, and helpful throughout the ordering process. Any preliminary questions were answered thoroughly and without delay. The overall transaction was smooth and efficient. This supplier clearly prioritizes reliability and customer satisfaction, making them a top choice for precision components. Highly recommended for anyone needing dependable, high-quality electrical terminals.

Naturally, the delivery was prompt and well-handled. The package arrived ahead of the estimated schedule, which was a pleasant surprise. Everything was securely packed, with no signs of damage during transit. The quality of the pins is immediately apparent; they feel solid and precisely made. The finish is smooth and consistent, exactly as one would hope for from a CNC machined component. Customer service was responsive and helpful when I had a pre-sale inquiry about specifications. They provided clear information without delay. Overall, a very satisfactory experience from ordering to receipt. The product appears to be manufactured to a high standard, and the logistical execution was flawless. This inspires confidence for future orders.

Prompt delivery and excellent packaging. The items arrived well-protected and ahead of the estimated schedule, which was a pleasant surprise. The build quality appears very high upon initial inspection; the machining is precise and the materials feel durable. Communication from the seller was clear and professional throughout the process, answering my pre-purchase questions quickly. Overall, a very satisfactory experience from order to receipt. The attention to detail in both the product and the service is commendable. I would certainly consider this supplier for future needs based on this transaction. The logistical efficiency made the procurement process seamless and stress-free. Packaging was robust, ensuring no damage occurred in transit, which is crucial for precision components like these. The quality of the terminals themselves meets the specifications discussed, showing good craftsmanship. Customer service was responsive and helpful, providing updates without needing to be prompted. This level of service builds trust and reliability. Perfect execution from start to finish, making the entire purchasing journey straightforward and positive. The combination of fast shipping, secure packaging, and apparent high manufacturing standards makes this a highly recommended source. Post-delivery support has also been proactive, checking to ensure everything was in order. Such thoroughness is rare and greatly appreciated in today’s market. Precisely what one hopes for when ordering specialized components online.

Perfect experience from start to finish. The packaging was exceptionally secure, ensuring every single pin arrived in pristine condition without a single bent or damaged piece, which is often a concern with such precise components. The quality of the machining is immediately apparent; the tolerances are exact and the finish is smooth and consistent across the entire batch, indicating high-precision manufacturing. Communication and service were outstanding. The team was responsive and proactive, providing clear updates throughout the process and promptly answering all technical queries. This level of attention to detail in logistics, product integrity, and customer support is commendable and makes sourcing these critical components a reliable and stress-free process. Highly recommended for anyone needing precision electrical terminals.

Fantastic experience overall. The shipping was remarkably fast, arriving well ahead of the estimated delivery window, which was a very pleasant surprise. The packaging was secure and professional, ensuring all components arrived in perfect condition without any bends or scratches. Regarding quality, the pins are exceptionally well-made. The precision machining is evident; the finish is smooth and consistent, and the dimensions appear to be exact. They fit perfectly into their intended connectors without any force or play, which speaks volumes about the manufacturing tolerances. The metal feels robust and of high grade, promising excellent conductivity and durability. Customer service was also top-notch. I had a pre-sale question about a specific detail, and the response was prompt, thorough, and very helpful. The communication was clear and polite throughout the entire process. It’s clear this supplier values their customers and stands behind their products. While I haven't installed these in a final assembly yet, the initial inspection for fit and finish is overwhelmingly positive. Based on the logistics, the tangible quality of the components, and the excellent support received, I would not hesitate to order from them again for future projects requiring precision electrical terminals.

Outstanding experience from start to finish. The shipping was remarkably fast and efficient, with the package arriving ahead of the estimated schedule and in perfect condition. The quality of the terminals is exceptional; they are precisely machined with a flawless finish and fit perfectly into their intended applications. Customer service was equally impressive, responding promptly to my inquiry with clear and helpful information. Overall, a very smooth and satisfactory transaction. I am thoroughly pleased with the entire process and the product received.

I am thoroughly impressed with the overall experience. The shipping was remarkably fast, arriving much sooner than anticipated. The packaging was secure and professional, ensuring the items were perfectly protected during transit. Regarding quality, the components feel exceptionally sturdy and well-made, with precise machining that meets high standards. The customer service team was responsive and helpful, promptly addressing my inquiries with clear and courteous communication. This level of attention to detail in logistics, product integrity, and support is commendable and makes the process seamless and reliable.

Outstanding experience from start to finish. The shipping was remarkably fast and efficient, with the package arriving well ahead of the estimated delivery date. Everything was securely packaged, showing clear attention to detail in the logistics process. Regarding quality, the components are simply excellent. The machining appears flawless, with a very precise and clean finish that speaks to high manufacturing standards. The metal feels solid and durable, exactly as one would hope for in electrical connectors. Customer service was also top-notch; any inquiries were answered promptly and professionally, making the entire transaction smooth and worry-free. Overall, a very reliable and satisfactory purchase where logistics, product quality, and service all exceeded expectations.