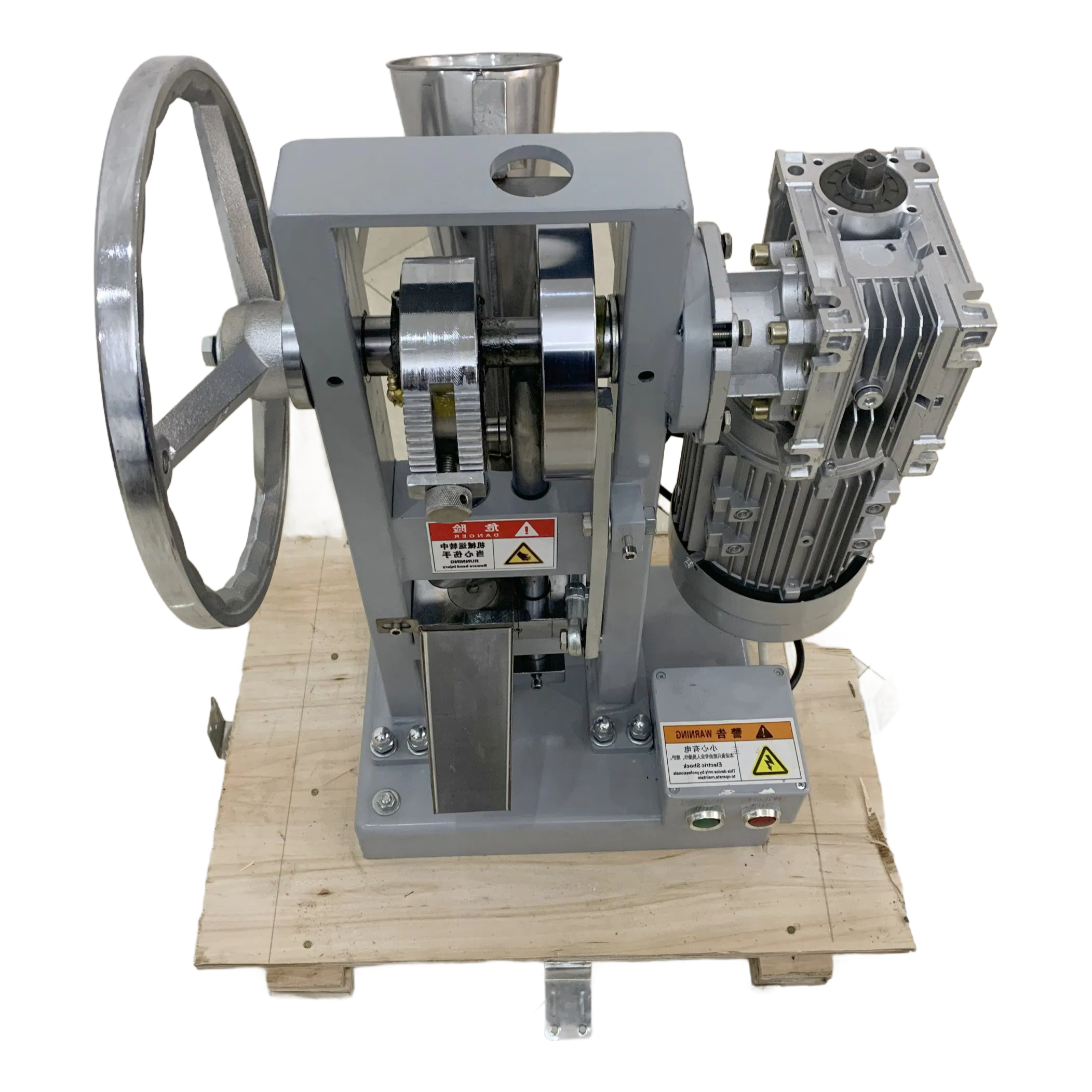

The single punch tablet pressing machine transforms powder or granular raw materials into precisely formed tablets ranging from 5-10mm in diameter. This versatile equipment can produce round, cylindrical tablets as well as custom-shaped tablets with text, trademarks, or patterns. With adjustable tablet weight, thickness, and hardness parameters, this machine offers exceptional flexibility for various production needs.

This tablet press finds extensive application across multiple industries including pharmaceuticals (both Western and traditional Chinese medicine tablets), food production (candy chips, coffee tablets), healthcare products (calcium tablets, propolis tablets), and chemical manufacturing (mothballs, catalysts). The machine demonstrates excellent material adaptability, particularly for non-adhesive powders.

Key operational features include both electric and manual pressing options, producing 3500-4000 tablets per hour in electric mode. The machine maintains consistent tablet quality with smooth surfaces and uniform weight distribution. Remarkably efficient, it requires only 200 grams of material for experimental batches, minimizing raw material waste.

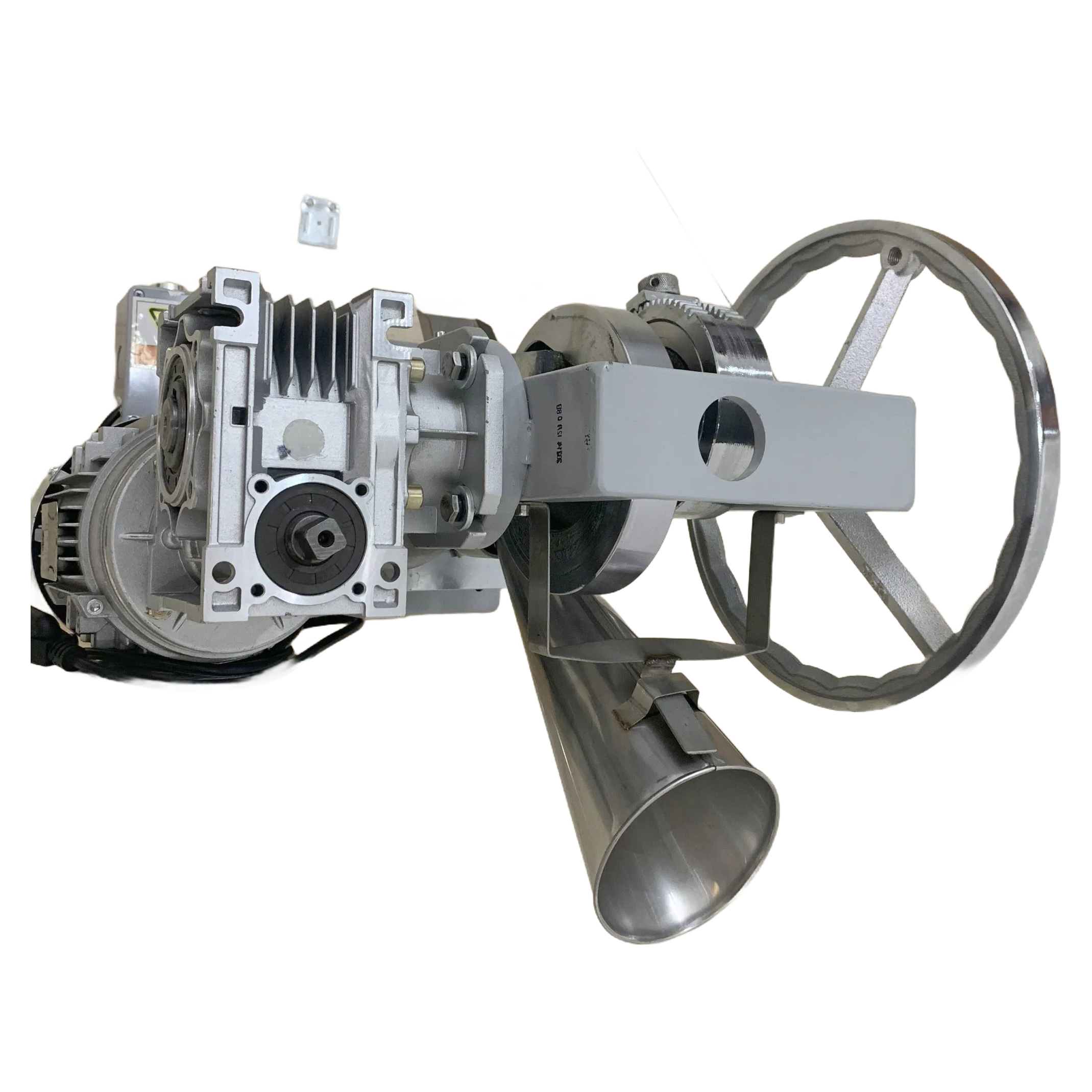

The robust construction features a cast iron body with high-hardness steel molds, ensuring durability and long service life. Operation requires minimal training, with most staff able to master basic functions quickly. Custom molds between 5-10mm can be manufactured to meet specific product requirements.

For optimal tablet production, materials should possess three essential characteristics: good fluidity for consistent filling, proper compression formability to prevent defects, and adequate lubrication to prevent sticking. While many applications require granulation prior to pressing, recent advancements in excipient technology have expanded direct powder compression possibilities.

Common tablet quality issues and solutions include: adjusting pressure or adhesives for loose tablets, modifying formulations or equipment settings for capping problems, controlling moisture content and lubrication for sticking issues, and optimizing disintegrant ratios for delayed dissolution. Regular quality checks during production ensure consistent output.

The machine's installation requires a stable work surface approximately 600mm high, with proper anchoring and electrical connections. Die assembly follows a specific sequence (lower die → middle die → bench plate → upper die → hopper) with careful attention to alignment to prevent friction or collision during operation.

Critical adjustments include tablet thickness (via lower punch alignment), filling depth (for weight control), and pressure settings (for hardness). Proper debugging involves test runs and gradual parameter optimization until desired tablet characteristics are achieved.

Operational safety requires attention to machine rotation direction, proper belt tensioning, and avoiding overloading. The upper punch should always be in the raised position before starting to prevent jamming. In case of machine stoppage, immediate power shutdown followed by careful troubleshooting prevents component damage.

Maintenance procedures include regular cleaning, lubrication according to manufacturer specifications, and periodic inspection of all moving parts. Proper die removal techniques prevent damage to precision components. When not in use, machines should be protected from dust and moisture.

Delivery was impressively fast and the packaging was secure. The machine arrived in perfect condition without any delays. The quality of the equipment is outstanding; it feels very robust and well-made. Customer service was responsive and helpful throughout the process, answering all my questions promptly. Overall, a very positive experience from start to finish. I would definitely recommend this supplier to others looking for reliable equipment. The entire transaction was smooth and professional. The attention to detail in both the product and the service provided is commendable. It’s clear they value their customers and take pride in their work. I am very satisfied with my purchase and the support received. This has been a seamless and efficient process from ordering to delivery. The team was courteous and knowledgeable, making the whole experience pleasant. I look forward to any future business with them. The machine itself looks exactly as described and seems built to last. Everything was handled with great care and professionalism. I couldn’t have asked for a better service or product. It’s refreshing to deal with a company that prioritizes customer satisfaction so highly. The logistics were flawless, and the communication was clear at every stage. A truly excellent experience all around.

Brilliant experience overall. The delivery was exceptionally fast, arriving well ahead of the estimated schedule, which was a fantastic start. Packaging was robust and secure, ensuring the equipment arrived in perfect condition without a single scratch. Regarding quality, the machine feels incredibly solid and well-constructed, with precise engineering evident in every component. It exudes durability and professional-grade craftsmanship. Customer service has been outstanding; the support team was responsive, knowledgeable, and proactive in providing all necessary documentation and pre-delivery updates. Communication was clear and prompt throughout the entire process. This direct supply from the factory certainly adds great value, making the procurement smooth and trustworthy. A highly satisfactory purchase from logistics to post-sale support.

My experience with this supplier was quite positive overall. The logistics were handled efficiently; the tablet press equipment arrived well-packaged and on schedule, which was crucial for our production timeline. There were no significant delays or damages during transit, indicating careful handling and reliable shipping partners. Regarding quality, the machine appears robust and well-constructed, matching the descriptions provided. It feels solid and suitable for industrial use, though only long-term operation will confirm its durability fully. The service aspect was commendable; the communication was clear and responsive from inquiry to post-delivery. They answered my questions promptly and provided necessary documentation. While I cannot yet comment on the machine’s performance or specific technical parameters, the initial impressions regarding delivery, build, and support are favorable. This has been a smooth transaction so far, and I appreciate the professional approach.

The delivery was incredibly fast and efficient. Tracking information was provided promptly, and the package arrived well ahead of the estimated schedule. Everything was packaged with exceptional care, ensuring the equipment arrived in perfect condition without a single scratch or dent. The overall quality of the tablet press machine appears outstanding upon initial inspection. The construction feels robust and durable, exactly as described for industrial use. Customer service has been responsive and helpful throughout the entire process, answering all pre-purchase questions thoroughly and providing clear post-delivery support information. This level of service makes the purchasing experience smooth and reliable. The communication was professional and timely, which is greatly appreciated when ordering such specialized equipment. From logistics to the initial quality check, this has been a highly satisfactory transaction that inspires confidence in both the product and the supplier.

Great experience overall. The shipping was incredibly fast and efficient. The equipment arrived well-packaged and ahead of the estimated schedule, which was a pleasant surprise. Regarding the build quality, it feels robust and precisely manufactured, exactly as described. The initial communication and post-delivery support have been very good and responsive. A smooth transaction from start to finish.

Zippy delivery was the first thing that impressed me. The shipment arrived ahead of schedule, which was a fantastic start. The packaging was robust and secure, ensuring the equipment was perfectly intact upon arrival. Regarding the machine's quality, it feels solid and well-constructed. The materials used seem durable and suitable for rigorous use. The overall finish and assembly are precise, reflecting good manufacturing standards. As for the service, the communication from the supplier was clear and professional from the initial inquiry through to post-delivery follow-up. They were responsive and provided all necessary documentation promptly. This combination of efficient logistics, apparent build quality, and attentive service made the entire procurement process smooth and satisfactory. I am pleased with this direct factory purchase experience and the support received.

Outstanding experience from start to finish. The logistics were handled impeccably; the equipment arrived well ahead of the estimated schedule, which was a fantastic surprise. Everything was packaged with extreme care, and there was no sign of damage whatsoever. The quality of the tablet press machine is immediately apparent. It feels robust, well-engineered, and the finish is professional. It clearly matches the description of being industrial-grade. Regarding service, the communication was prompt, clear, and helpful throughout the entire process. All my pre-shipment inquiries were answered thoroughly and without delay. The post-delivery support has also been proactive, checking in to ensure everything arrived in order. Overall, a very smooth and satisfactory transaction. The combination of efficient logistics, apparent high quality, and excellent customer service makes this a highly recommended supplier. I am confident in the durability and performance of this machine based on this initial experience.

I am thoroughly impressed with the overall experience. The delivery was remarkably fast, arriving much sooner than the initial estimate provided. The packaging was exceptionally secure, with no signs of damage to the robust crating. Every component was meticulously protected. Regarding the machine’s build, the quality is outstanding. The materials feel premium and the construction is solid, exactly as described for industrial use. The communication from the supplier was consistently prompt and helpful throughout the entire process, from initial inquiry to post-delivery follow-up. They provided clear documentation and were very responsive to questions. This level of service, combined with the obvious quality of the equipment and the efficiency of the logistics, makes for a highly satisfactory purchase. I would not hesitate to recommend this supplier to others in the industry seeking reliable equipment.

Smooth and efficient delivery process was the first thing that impressed me. The logistics were handled exceptionally well, with clear tracking updates and timely arrival. The packaging was robust and secure, ensuring the equipment arrived in perfect condition without any damage. Regarding quality, the construction feels solid and durable, exactly as described. It has a professional and sturdy build that inspires confidence for long-term use. The service provided was outstanding from start to finish. The support team was responsive, knowledgeable, and very helpful in addressing all pre-shipment inquiries promptly. Overall, a highly satisfactory experience with this supplier. The combination of reliable logistics, apparent high quality, and excellent customer service makes this a commendable purchase. I would certainly consider them for future needs and recommend them to others looking for similar equipment. The entire transaction was seamless and professional, which is always appreciated when dealing with industrial machinery.